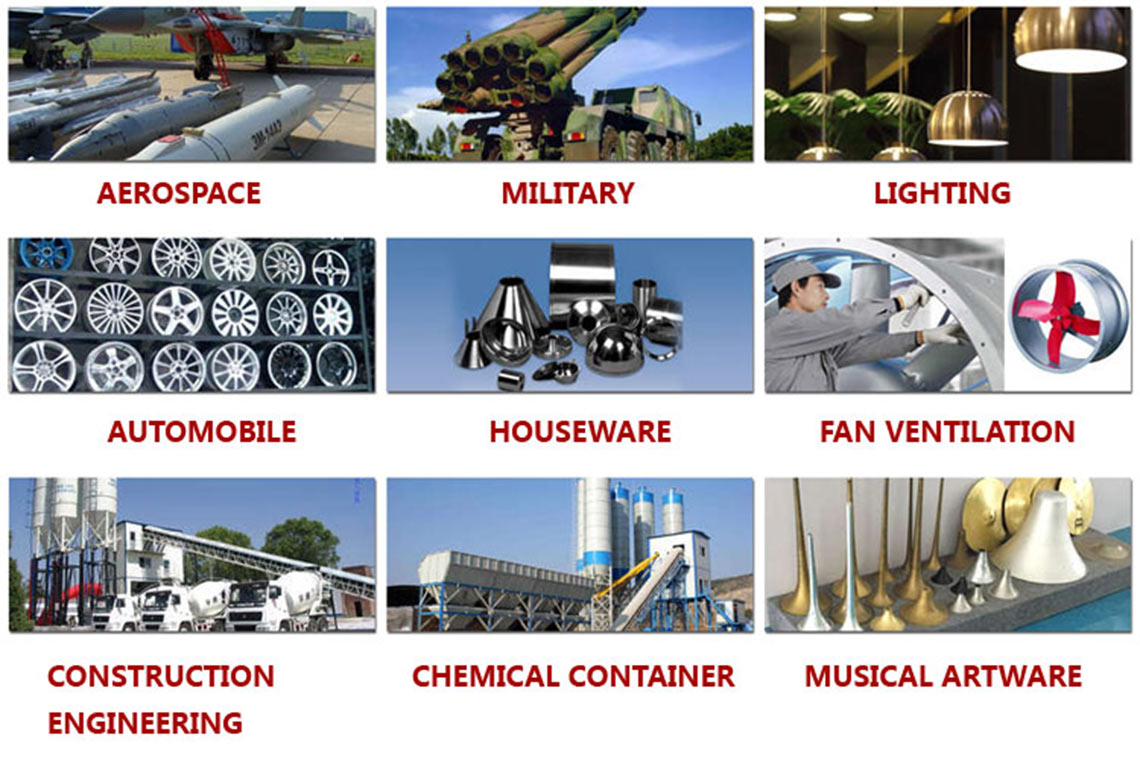

Full functional /High Performance/Large-Diameter CNC Spinning Machine is to meet the need of the spinning products of the industry, especially for the product such as House wares, Light equipment, Engineering, Chemical industry and Aerospace industry, etc.

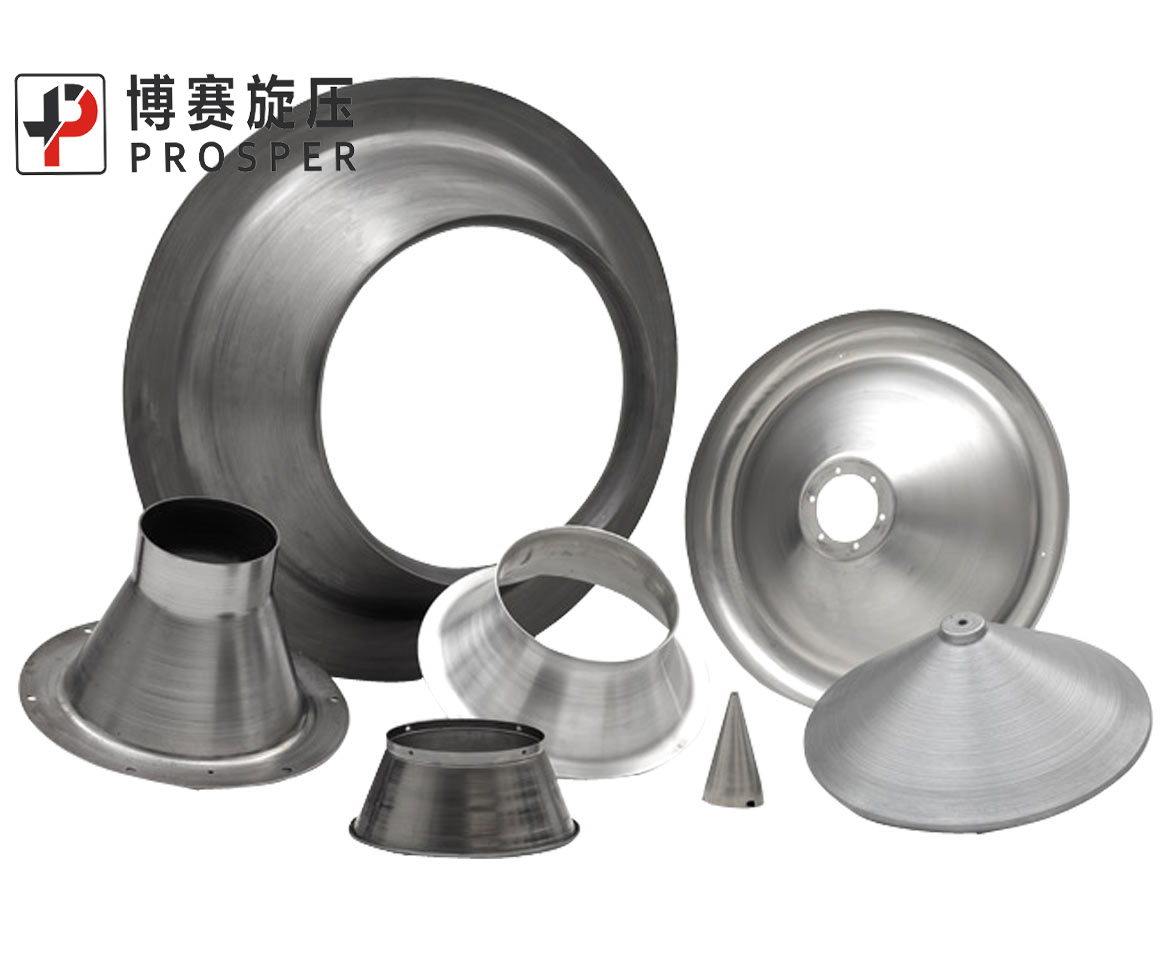

This series of machine are characterized by their highly efficient and cost-effective benefits they can provide. The spinning process technology can produce various shapes of products, such as in shapes of cylinder, cone, parabola, trumpet and bullet. It not only produces in large quantity, but also carries out the trial-manufacture testing and completes the trimming and rolling of the edge and contraction and extrusion of the products. The machine is suitable for processing of the aluminum alloy plate, steel plate, stainless steel plate and many other materials.

Spinning of major diameter products

Spinning of products that not achievable by human labor

Substitution of drawings/reduction of cost

Optional dual spindle to reduce mandrel cost

Excellent cost effective/economical and practical

High strength cast machine body

Computerized SIEMENS Numerical Control System

Spinning tools turret/rollers

Heave duty guide and ball screw

High torgue/high speed spindle

Material centering

Tool offset

Digital integrated hydraulic system

Digital integrated lubrication system

BA units

BE units

Manipulator

Prosper Spincad programming software

Second spindle

Power unit

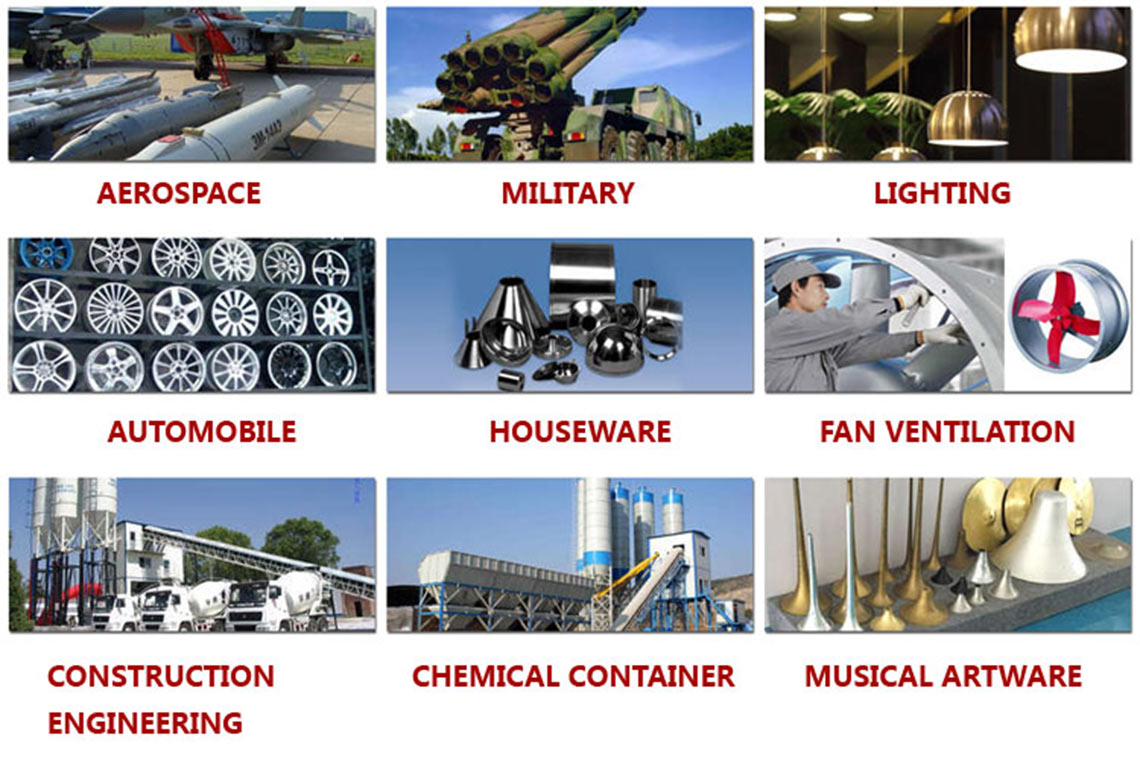

Applications:Lighting,kitchenware,packings Spinning of major diameter products Spinning of bog thickness material Spinning of products not achievable by human labor Substitution of drawing/reduction of cost Optional dual spindle to reduce mandrel cost Excellent cost

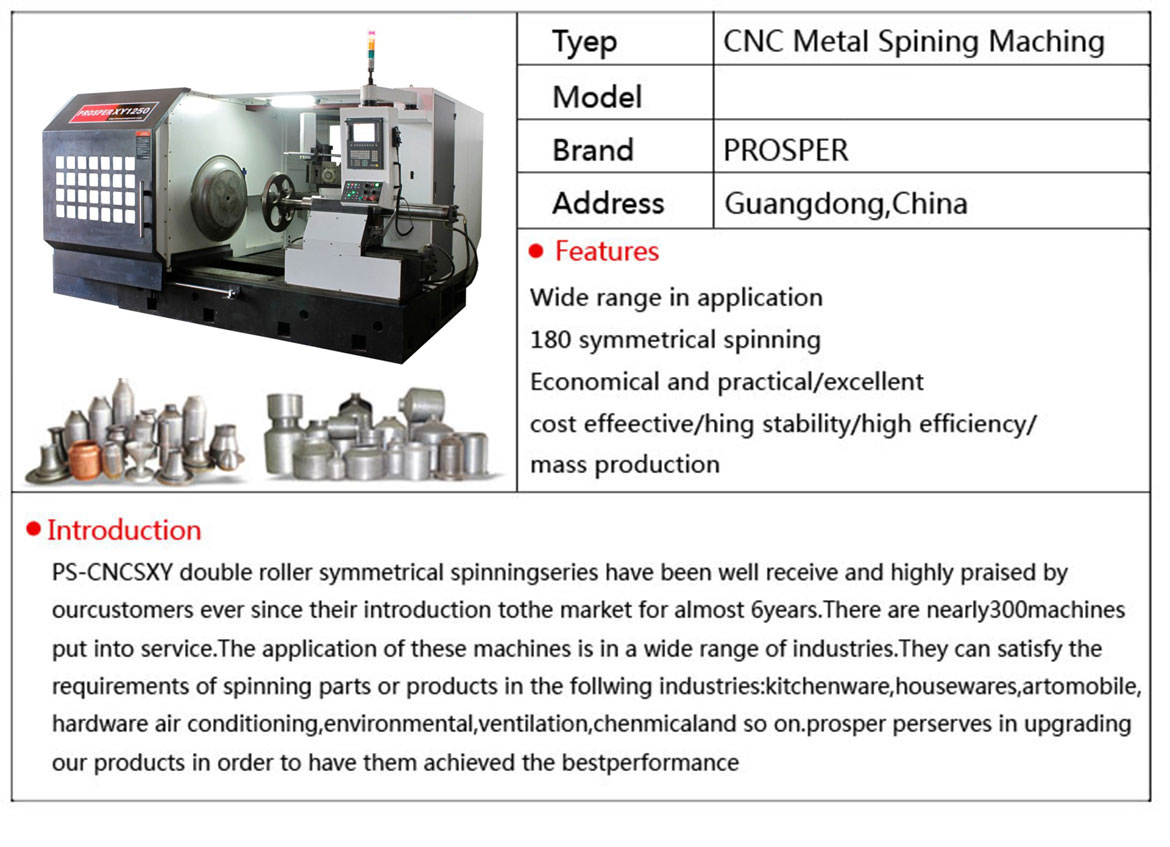

Technical Data:

|

Parameter |

Unit |

PS-CNCXY1300 |

|

Workpiece Diameter |

mm |

1300 |

|

Main spindel power |

Km |

30 servo |

|

Tailstock travel |

mm |

1000 |

|

Z axis travel |

mm |

750 |

|

X axis travel |

mm |

500 |

|

Tailstock force |

Kn |

60 |

|

Tailstock travel |

mm |

120 |

|

Tools positions |

|

4 HD |

|

AI/CU Appx.thickness |

mm |

0.5-5.0 |

|

Steel Appx.thickness |

mm |

0.5-4.0 |

|

S/S Appx.thickness |

mm |

0.5-3.0 |

The application of these machines is in a wide range of industries.They can satisfy the requirements of spinning parts or products such as :Military Aerospace/aviation Automobile Chemical and so on.

-

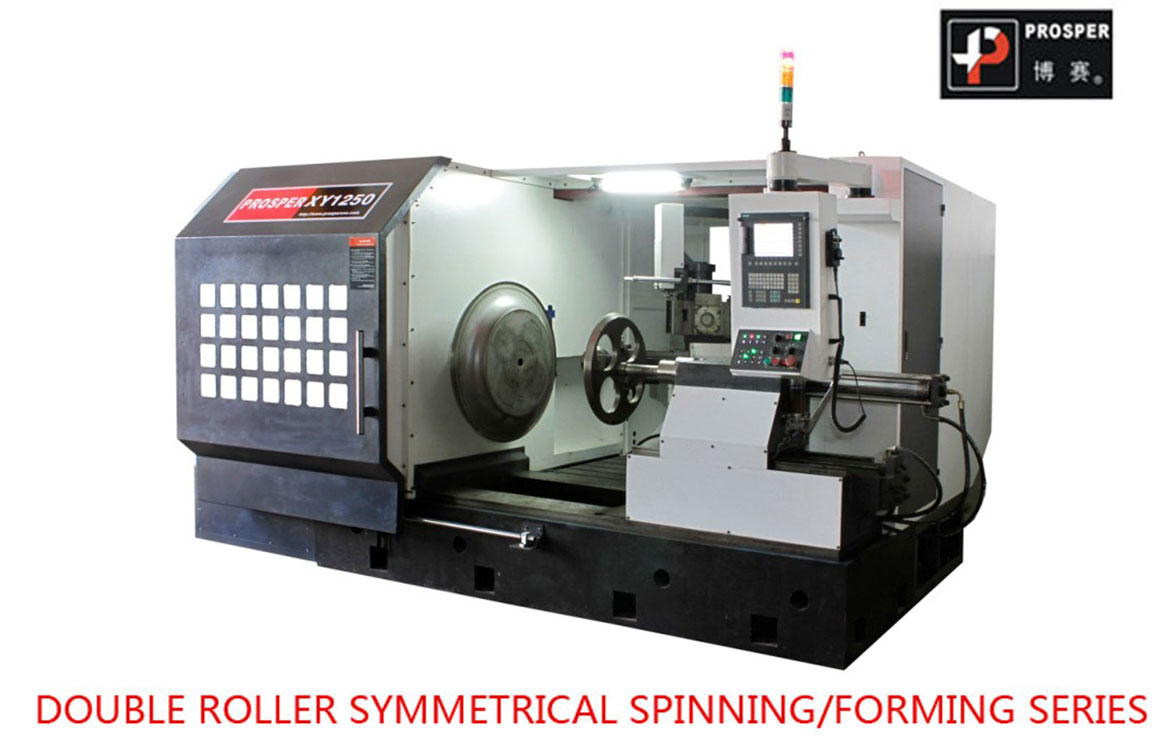

1. This series of equipment has powerful function with wide extensive product range, solid structure, highly stability. The machine body adopted high strength casting with 3d overall design.The sliding table and the system design adopt the multi-angle optional mode, which greatly increases the spinning strength.

-

2. The machine tool can be equipted with fully automatic production line with the manipulator to receive high production

-

3. The machine tool can realize positive spinning, reverse spinning, normal spinning, shearing spinning, staggered distance spinning, core die spinning no core die spinning.Including trimming, flanging, flanging, indentation, rolling and other processing.

-

4. The machine adopts Germany Siemens SINUMERIK 828D multi-axis servo valve control system (Prosper secondly development), which has core mould protection function, automatic detection of each unit when starting up, automatic lubrication, fault diagnosis and overload protection.

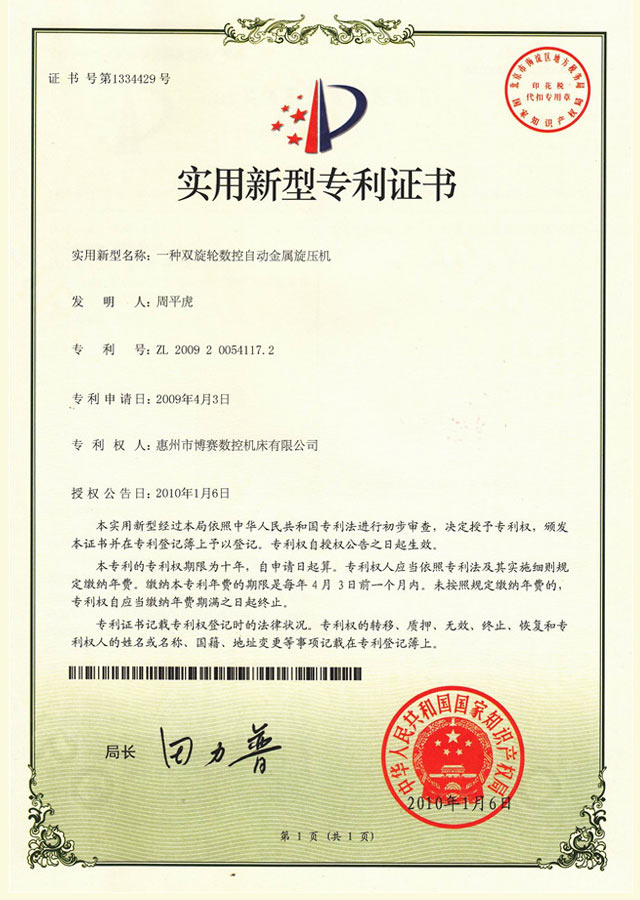

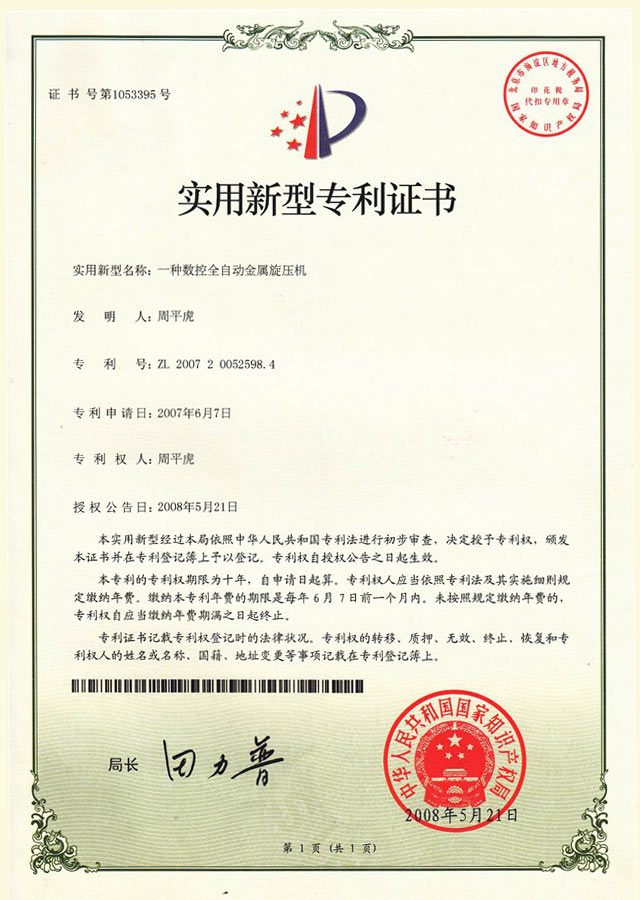

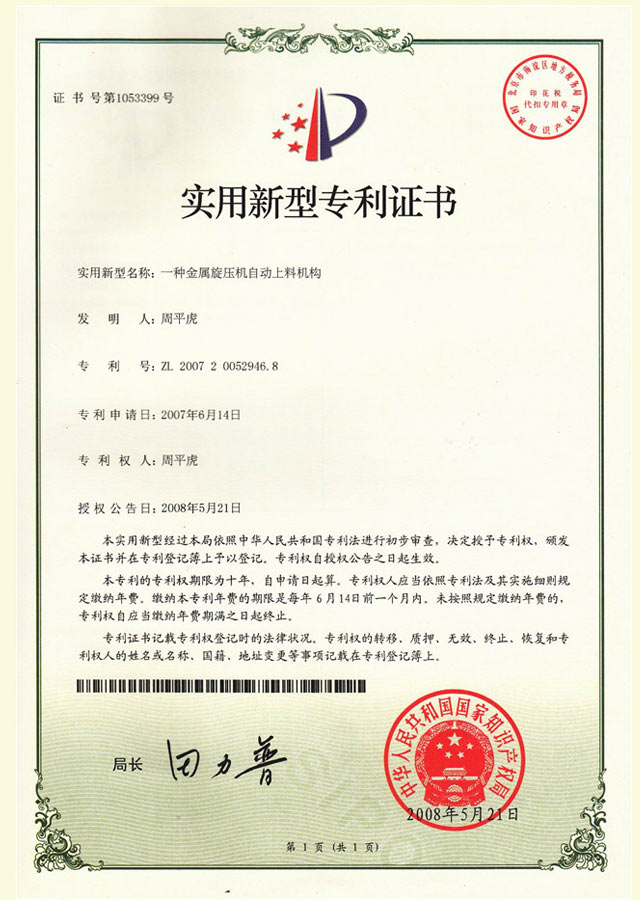

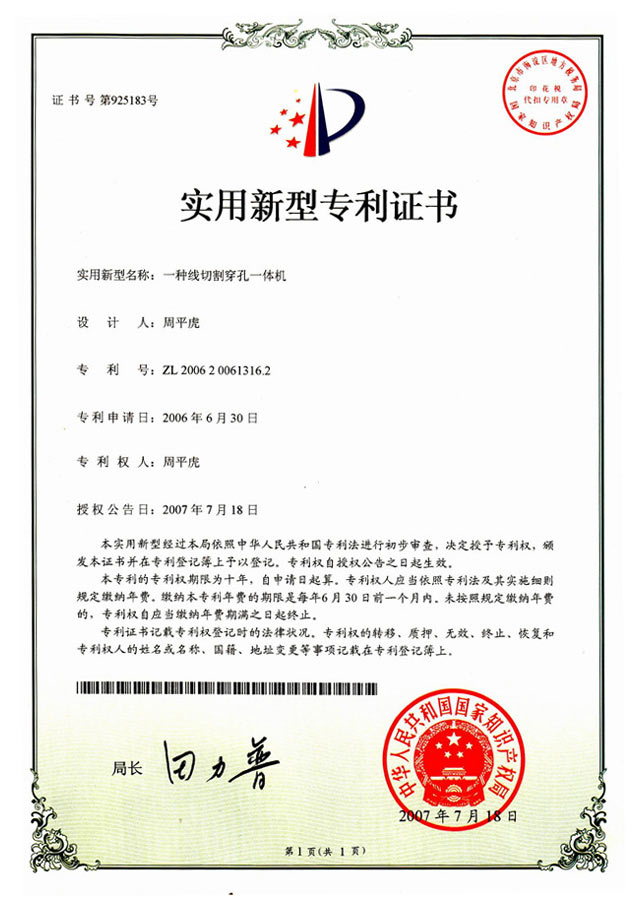

About Prosper

GuangDong Prosper CNC Machine Co.,Ltd is an enterprise of industrialization of new high technology which integrates research center,manufacturing,sales,customer service,and education and training school.After almost 20 years development,Prosper has nowadays owned a fifty thousand square meters operation site.Prosper values the quality of our products and services. We endeavor to provide the products and services of the most competitive advantage to our customers!

Assembly shop

The technology of workshop

The spinning experience pavilion

The technology of workshop

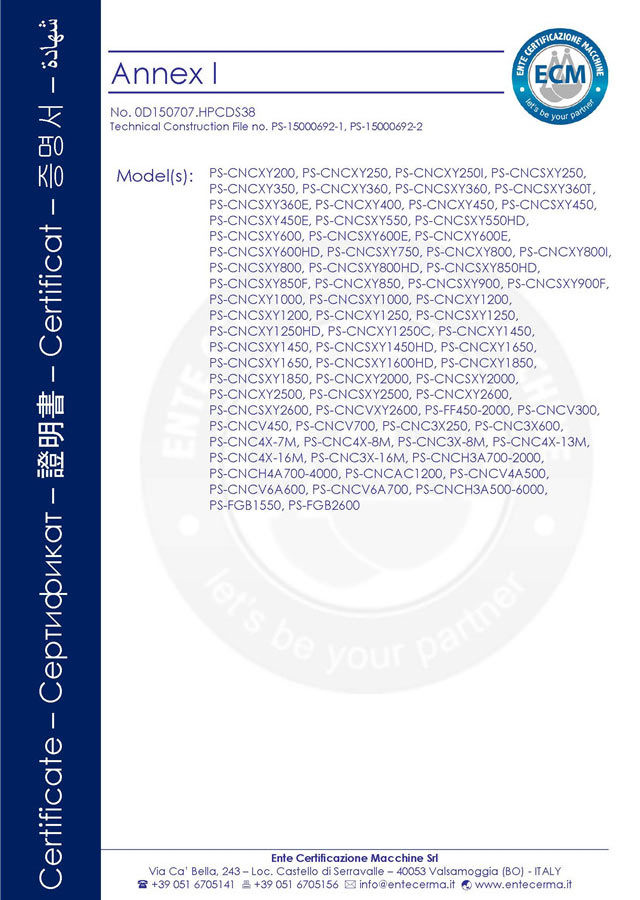

Prosper Core Technology

Application field

Cooperation strategic partner