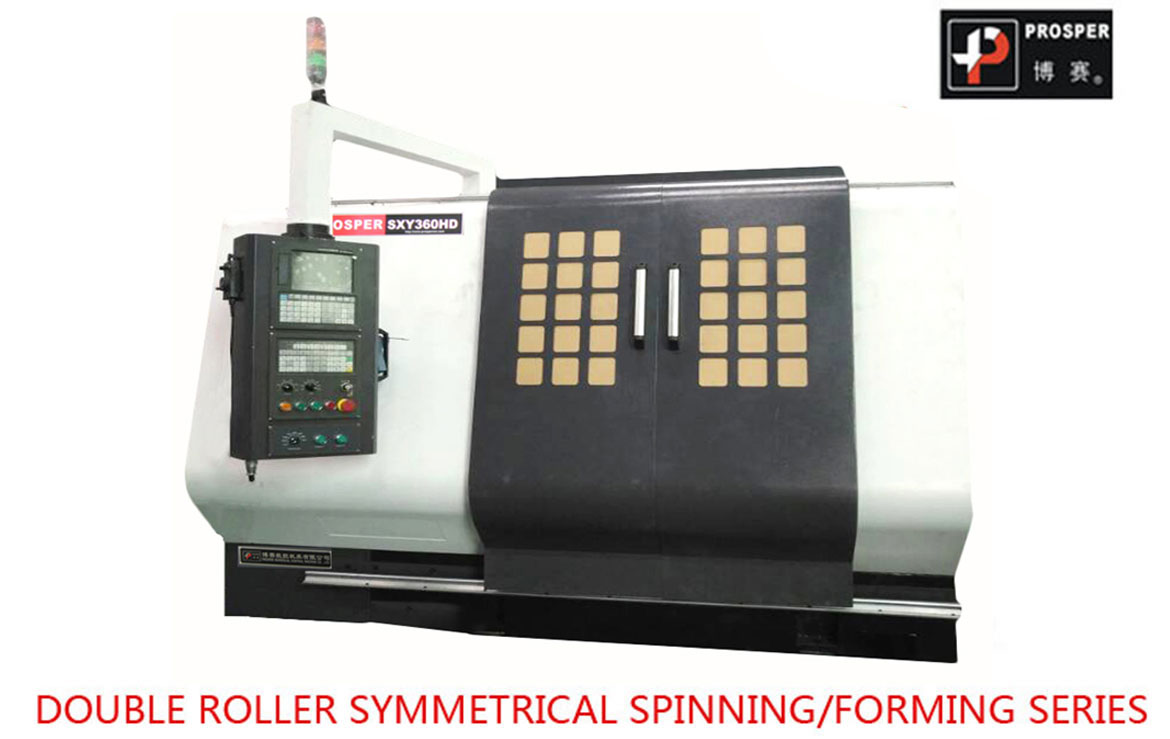

High Performance /High Compressive Stress 2-roller Spinning Necking Machine is specially developed for the production needs of the tubular spinning parts of the exhaust system of the automobile industry. The utility model has the advantages of practical functions, strong professionalism, high production efficiency, batch production and trial production of the barrel type and tube type products, and the products of trimming, turning, Chamfering and other processing functions.

The spindle of the machine adopts an independent spindle unit, and the bearing adopts high quality and high precision bearings to ensure that the spindle has good motion precision, stiffness and stability. The spindle drive adopts the large torque servo motor to ensure the constant output of the torque when the spindle is high and low. Using high strength spindle and whole casting slide to enhance mechanical strength;

Slide guide rail adopts high precision six face guide roller guide to ensure high strength and high precision;

The machine tool rotary motion drive mechanism is equipped with high-strength ball screw and double-nut ball screw unit. It adopts split forward and reverse ball screw and double-roller synchronism processing, which has good rigidity, workmanship and efficiency.

The spinning tool library is controlled by the system, multi position automatic switching function, and with the tool, cutting, scraping, trimming and shaping functions are realized.

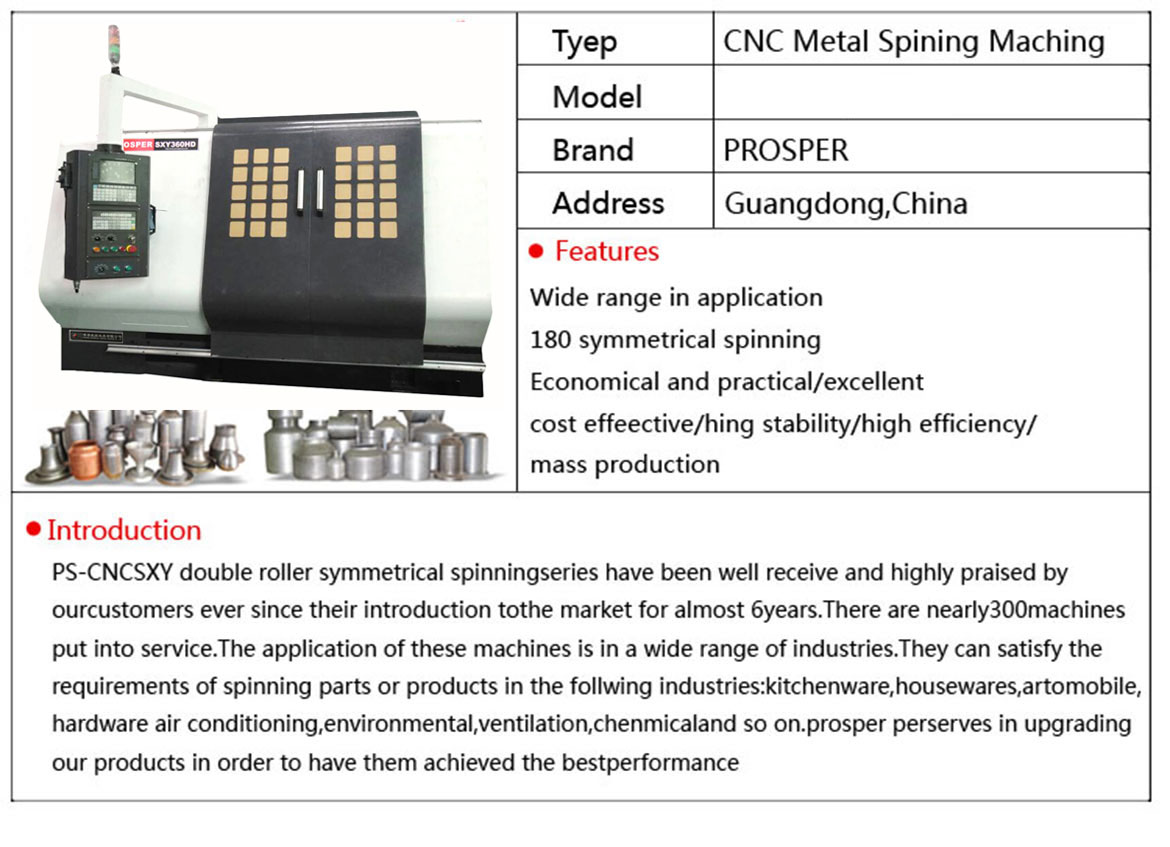

Technical Data:

|

Parameter |

unit |

PS-CNCSXY160P |

PS-CNCSXY360P |

PS-CNCSXY360PS |

|

MAX DIAMETER OF PIPE |

mm |

160 |

130 |

150 |

|

MAX LENGTH OF PIPE |

mm |

800 |

600 |

600 |

|

THICKNESS OF ALUMINUM ALLOY |

mm |

3 |

3 |

3 |

|

THICKNESS OF CARBON STEEL |

mm |

2 |

2 |

2 |

|

THICKNESS OF STAINLESS STEEL |

mm |

1.5 |

1.5 |

1.5 |

|

Z-AXIS STROKE |

mm |

300 |

300 |

300 |

|

X-AXIS STROKE |

mm |

400 |

400 |

400 |

|

AXIS MOTOR POWER |

NW |

10*2 |

10*2 |

11*2 |

|

SPINDLE MOTOR POWER |

KW |

7.5伺服 |

7.5伺服 |

7.5伺服 |

|

SPINDLE SPEED |

RPM |

1200 |

1000 |

1000 |

|

PROCESSING DEVICE |

|

2*180度转塔 |

2*180度转塔 |

2*180度转塔 |

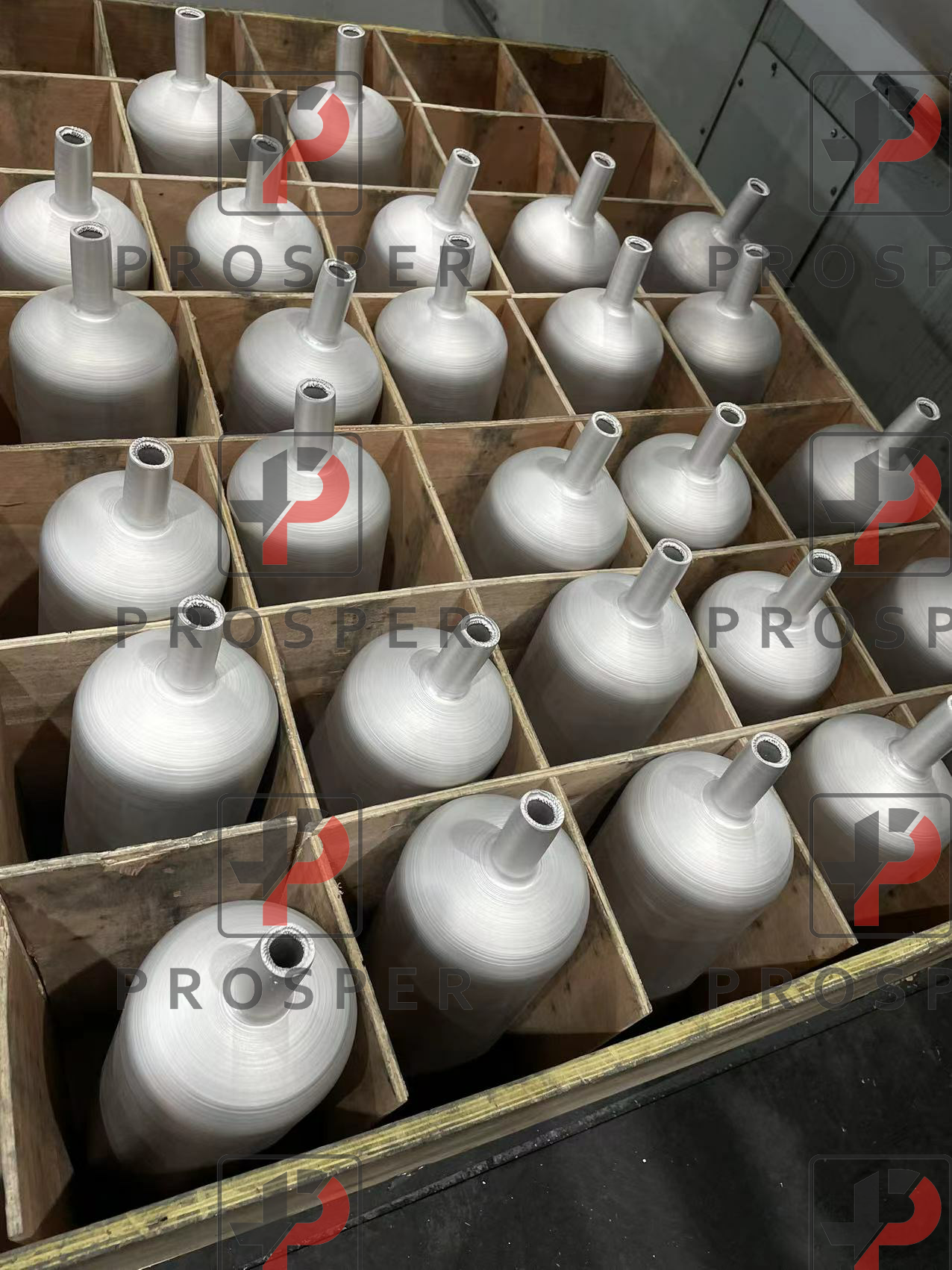

Applications:Lightings、metal art crafts、hardwares

Best spinning solution for small to medium diameter/thickness product

Excellent cost effective/economical practical

High Efficiency/High stability

Match With automatic material loading system

About Prosper

GuangDong Prosper CNC Machine Co.,Ltd is an enterprise of industrialization of new high technology which integrates research center,manufacturing,sales,customer service,and education and training school.After almost 20 years development,Prosper has nowadays owned a fifty thousand square meters operation site.Prosper values the quality of our products and services. We endeavor to provide the products and services of the most competitive advantage to our customers!

Assembly shop

The technology of workshop

The spinning experience pavilion

The technology of workshop

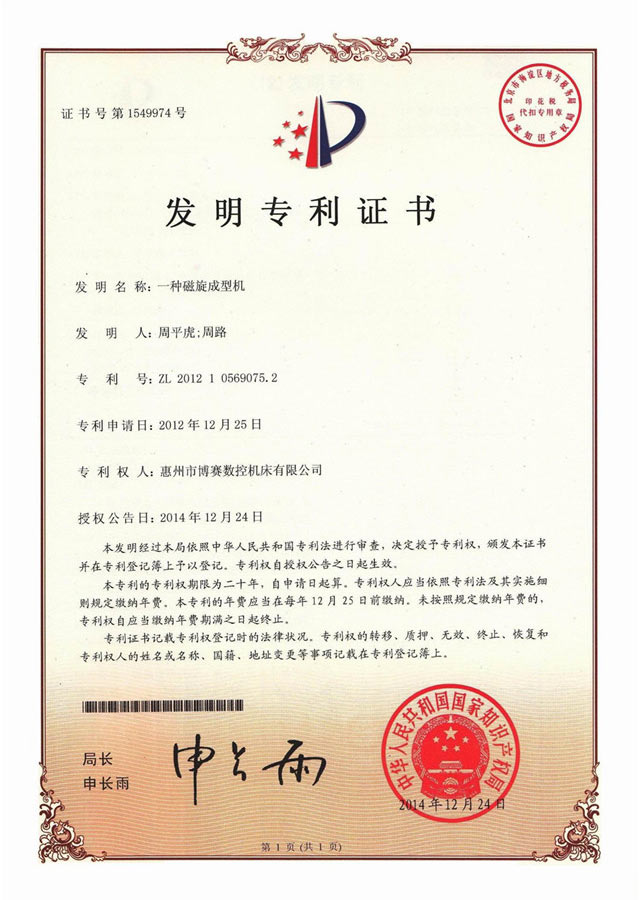

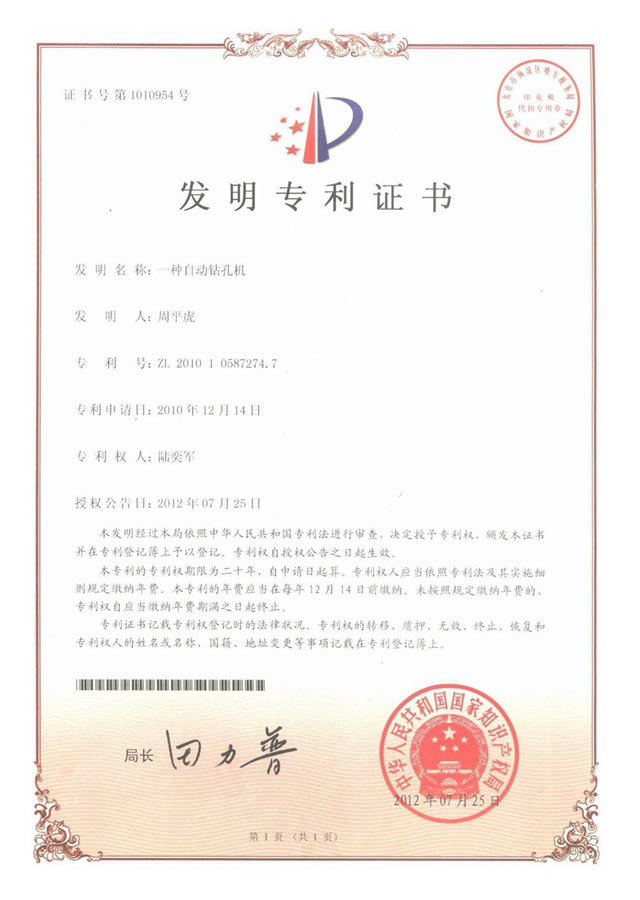

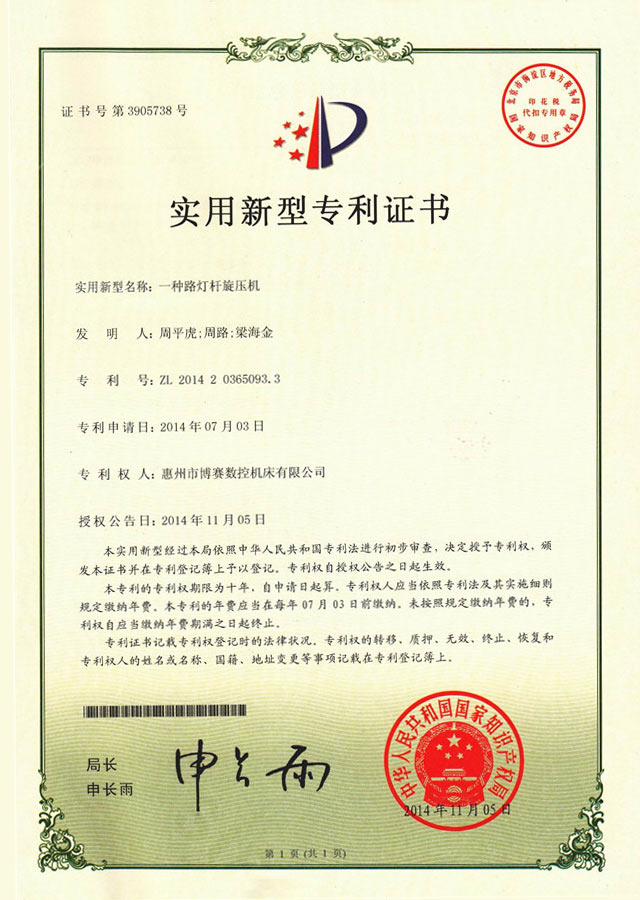

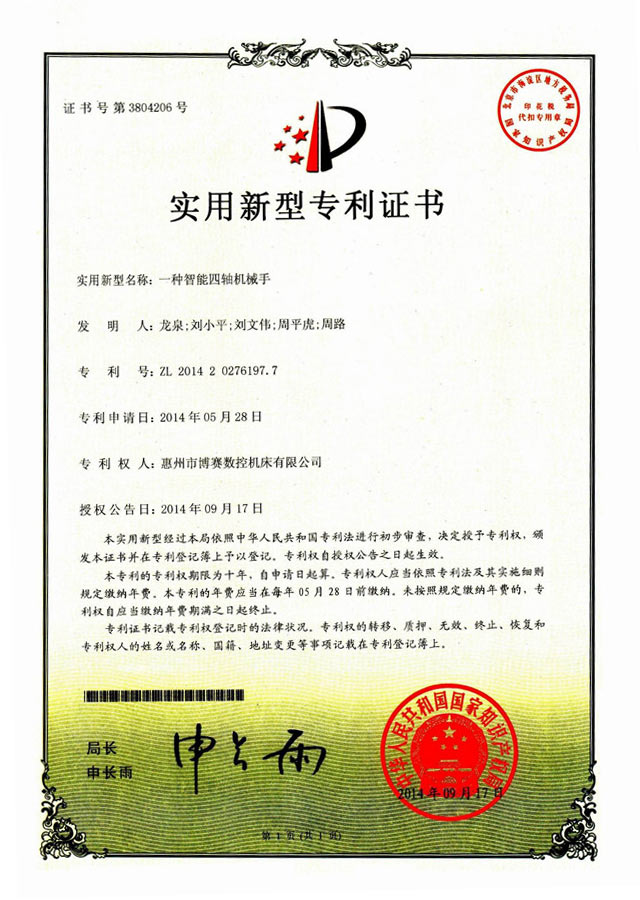

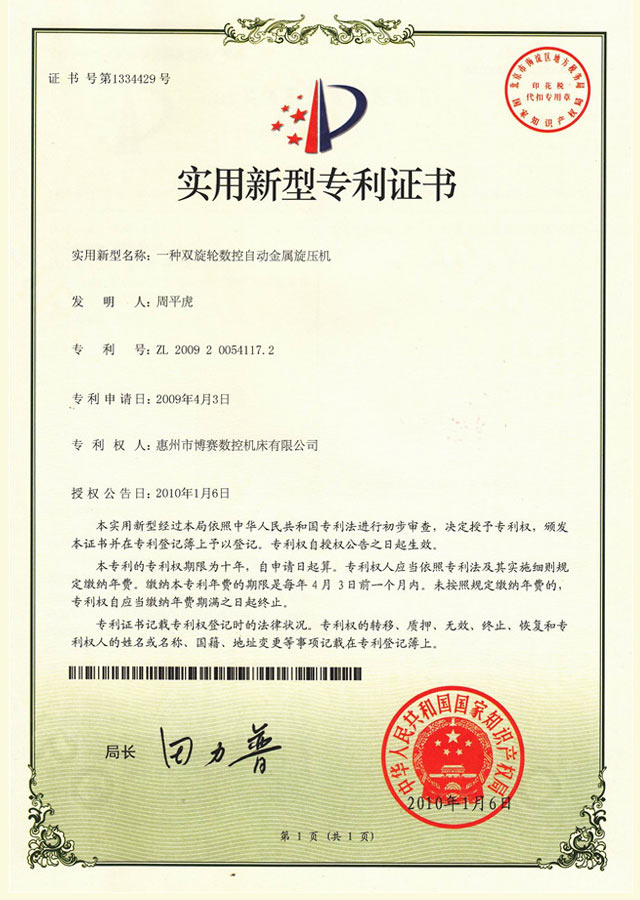

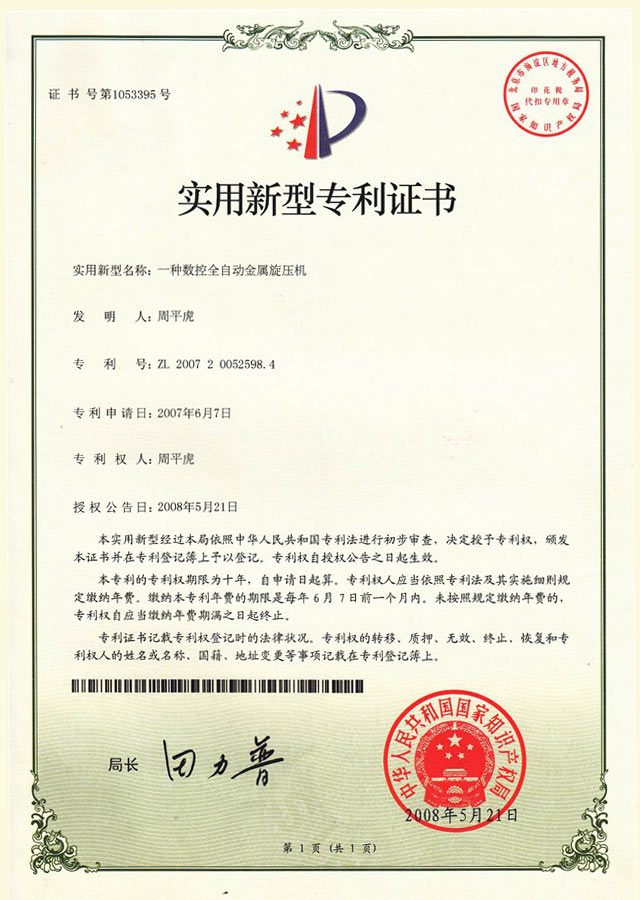

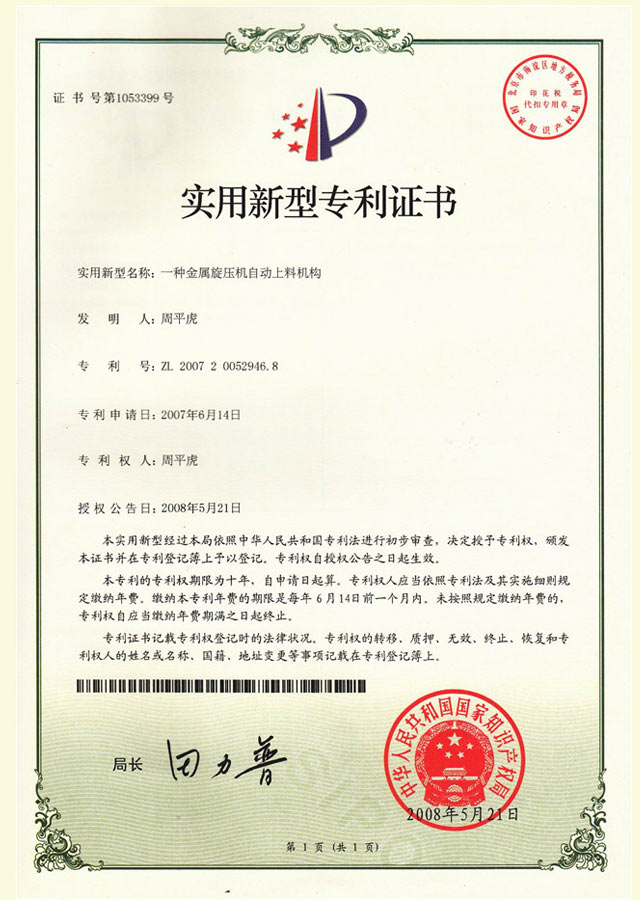

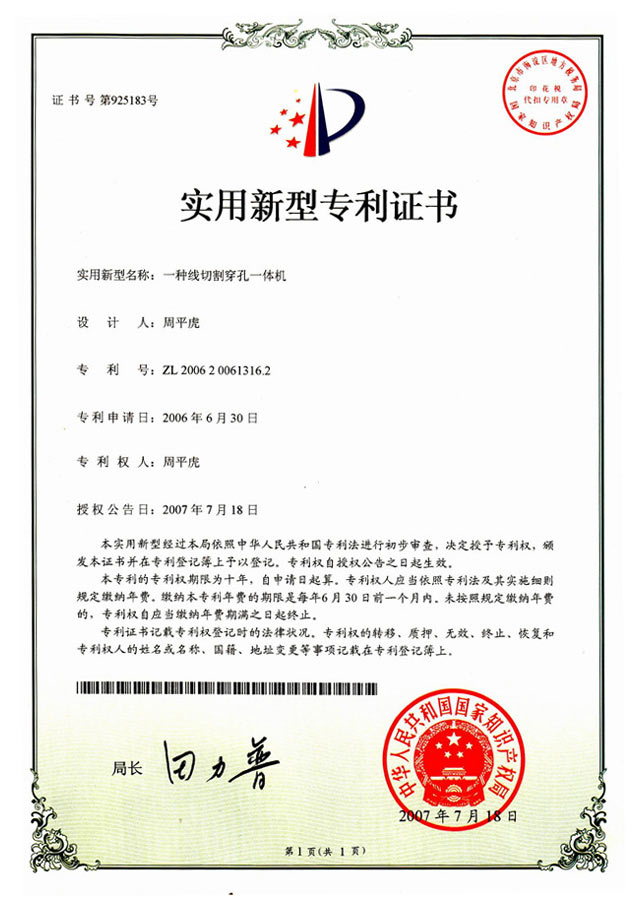

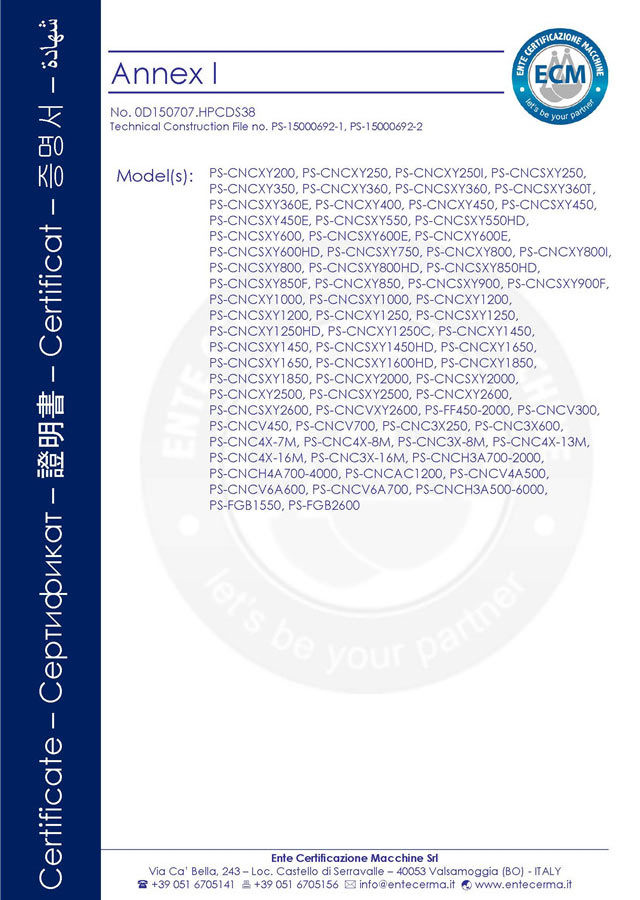

Prosper Core Technology