Composition of Spinning Equipment

Date: Jul,08 2020 View:

Composition of Spinning Equipment

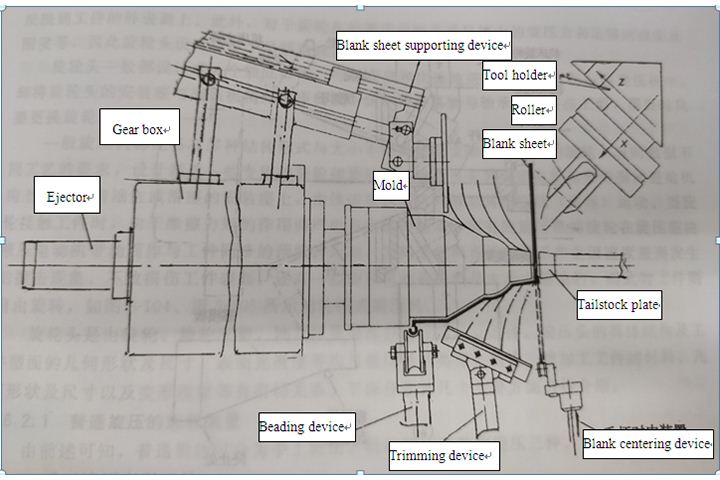

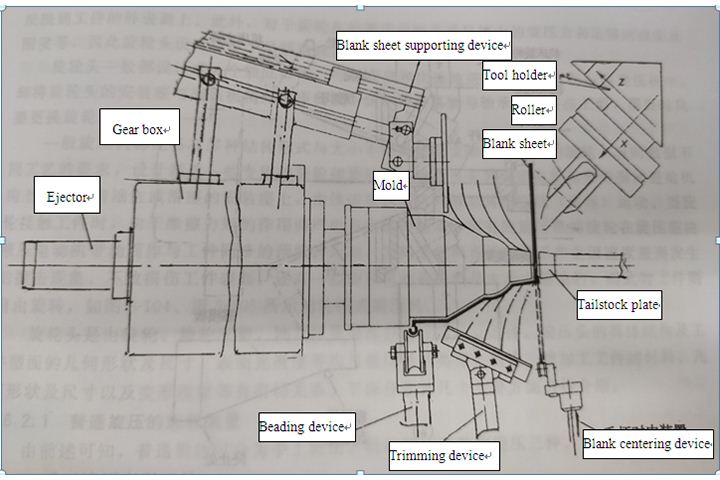

Generally speaking, all devices outside the main body of the equipment and used in the spinning process are collectively called spinning process equipment. In addition to the simpler manual spinning process equipment, the ordinary spinning process equipment and the powerful spinning process equipment are basically the same, with tooling molds such as rollers, mandrels, tailstock plates and profiling plates.

The roller is a spinning tool that forces the workpiece to undergo plastic deformation. The mandrel and the tailstock plate support and fasten the workpiece. The mandrel determines the inner shape of the spinning piece, and the outer shape of the spinning piece is made of a copy plate controlled or controlled by computer. Spin forming is directly realized by these devices. They have a very important influence on the quality of the spinning parts. Therefore, the correct design and manufacture of these devices is the basic premise for ensuring the quality of the spinning parts. In mass and batch production, the service life of these devices is also an important factor affecting their economy. In short, the requirements for its design and manufacturing should be very strict and should be given sufficient attention.

In order to meet the needs of certain process integrity, in addition to the above basic process devices, some auxiliary process devices, such as the blank centering device, the blank supporting device, the workpiece edge trimming device, workpiece loading and unloading devices and shaping (flanging or beading) devices, etc. With these auxiliary process devices, complete processing of the workpiece can be completed.

In the spinning production, in order to meet some special needs, there are some other forms of process equipment. For example, for a slab blank sheared and spun into a tapered piece with a pointed tip (such as a conical hood), the tailstock plate cannot be used to tighten, but it also needs to transfer the spinning torque, so a special synchronization fixture is required. Another example is that when the tubular member is rotating, a special snap ring is needed to clamp the workpiece. In addition, when spinning with tension in order to improve the axial flow of the material during spinning, a process device capable of generating such additional tensile stress is also required, and so on.

When large-scale shaped parts are produced in single parts and small batches, the manufacturing of large-scale mandrels is both cumbersome and uneconomical. When the dimensional accuracy requirements are not strict, core-less molds and roller-mold spinning may be considered.

For the heating spinning process, the spinning equipment also needs to be equipped with heating devices, generally various flame spray guns, electric induction heaters, etc. These devices should be able to move synchronously with the feeding of the roller. For the hot closing of steel gas cylinders and the back-spin spinning, a special heating furnace needs to be configured. At the same time, there should be cooling and heat insulation protection facilities for the equipment and related process devices.

According to their production tasks and process requirements, some of the above-mentioned auxiliary process devices should be included in the automatic program.