Metal Spinning and Its Development History

Date: Feb,24 2021 View:

Metal Spinning and Its Development History

Metal spinning forming is a symmetrical rotary forming process for metal. The principle is that the spindle drives the blank and the mold core to rotate, and then the rotating roller is used to apply pressure to the rotating blank. Due to the rotary motion of the longitudinal and lateral feed motion of the tool, this local plastic deformation gradually extends to the entire blank, thereby obtaining hollow rotating parts of various shapes.

Spinning is a special forming method. The spinning method can be used to complete the drawing, flanging, necking, bulging and curling of various shapes of rotating bodies.

According to the literature, the ceramic blanking method provides a process reference for metal spinning. The common metal spinning process has appeared in the early 10th century, which can spin a variety of silver, tin, and copper products. In the late 1860s, the first metal spinning patent appeared in Germany.

The first generation of spinning technology, of course, is manually powered. A total of two people are required. One person turns the big wheel to provide the spinning source power, and the other uses a rod tool to shape the blank material. The second generation of spinning is mainly powered by water and steam, and the emergence of electric motors. The third generation of spinning power has appeared. The spinning tools have changed from wood to metal wheels.

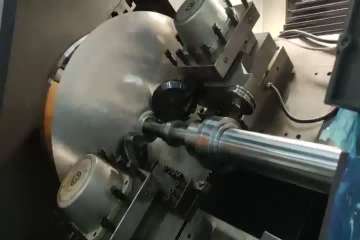

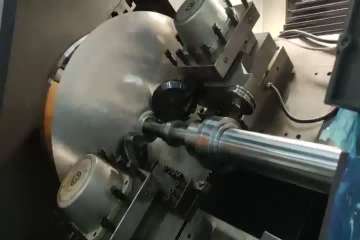

After the middle of the 20th century, spinning was generally mechanized, and hydraulic power source appeared. In the late 1960s, CNC spinning technology appeared. Therefore, it has moved from small batch production to large-scale production.

Up to now, foreign metal spinning technology has developed rapidly, the size range can reach 5~5000mm, the wall thickness is 0.2~150mm, the ratio of length to diameter is more than 20, the ratio of diameter to wall thickness is more than 750, and the spinning cylinder is the largest The diameter is 7600mm and the maximum mass is 60t.