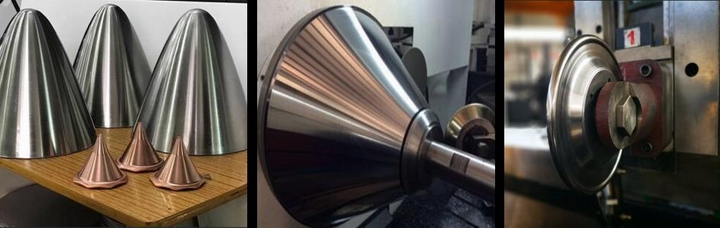

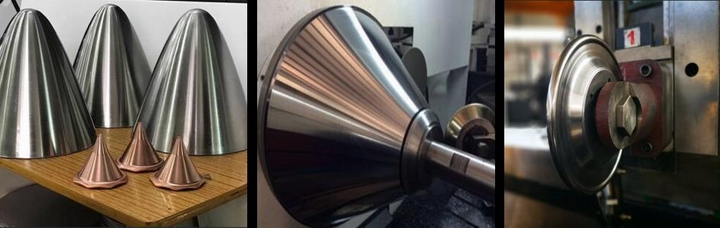

What is Metal Spinning?

Date: Dec,10 2019 View:

What is Metal Spinning?

The spinning chip less forming process is to make the metal circle blank. Tube billet and pre-formed material enter a rotary motion. The rotating metal blank is squeezed by the forming roller and the metal begins to flow. This process can obtain a variety of hollow bodies with complex generatrix shapes small tolerance ranges, excellent material properties and surface quality with minimal tooling cost. The spinning process accurately determines the wall thickness and profile of the workpiece and accurately repeats the wall thickness and contour.

The materials used for spinning process are varied, such as carbon steel, aluminum, stainless steel, copper and brass. Sometimes precious metals such as gold, silver and platinum are processed. Recently, rare metal such as molybdenum, tungsten, tantalum, titanium and other high hardness metal processing commission business is also increasing. The spinning application field covers lighting, kitchenware, aerospace, aviation, automobile, military, chemical, fan, air conditioning, power, ventilation, house wares, packing, artware, construction, hardware, engineering, musical instrument, medical, agriculture, gas, communication, motorcycle, shipbuilding and rail transit.