Technical Data:

|

APPLICATION |

|

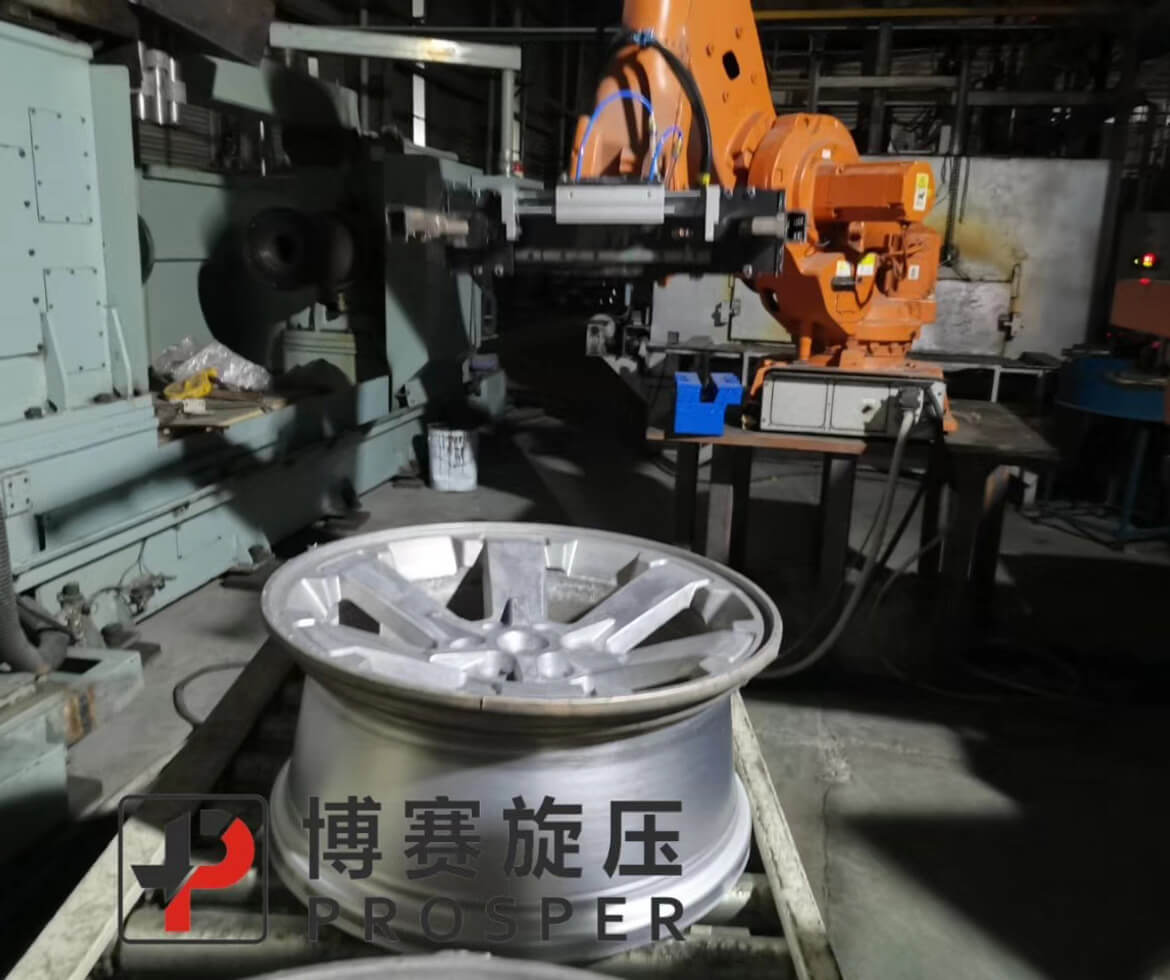

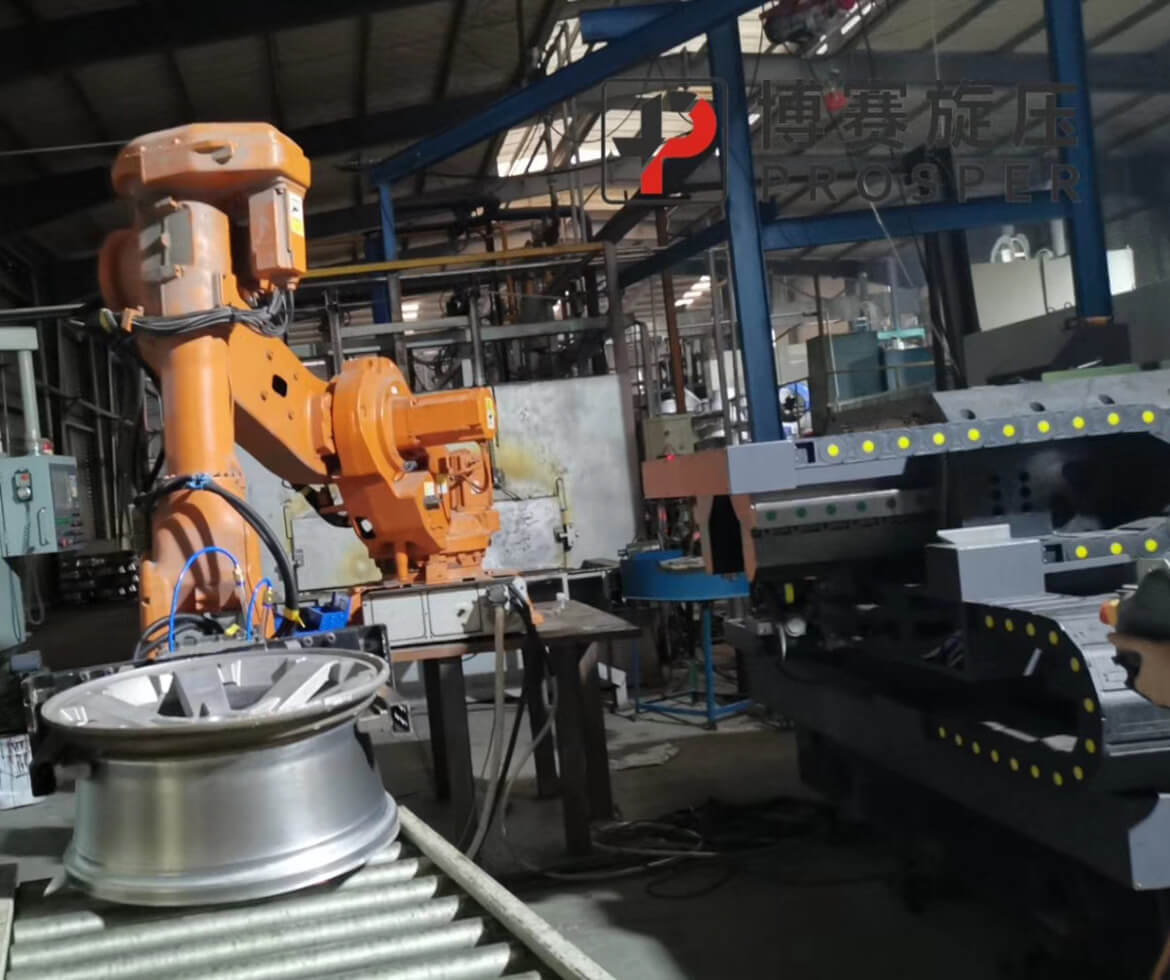

Casting/Forging Aluminum Wheel |

Casting/Forging Aluminum Wheel |

Casting/Forging Aluminum Wheel |

|

Maximum rotation diameter |

mm |

600 |

720 |

720 |

|

Minimum rotation diameter |

mm |

320 |

410 |

410 |

|

Max double center distance |

mm |

700 |

900 |

1100 |

|

Tool position |

PCS |

2 |

2 |

3 |

|

Longitudinal sliding table stroke |

mm |

460 |

520 |

600 |

|

Transverse sliding table stroke |

mm |

200 |

200 |

200 |

|

Longitudinal sliding table force |

Kn |

250KN*2 |

400 |

400KN*3 |

|

Transverse sliding table force |

KN |

250KN*2 |

400 |

400KN*3 |

|

Main spindle motor power |

KW |

2*100KW |

2*132KW |

2*132KW |

|

Tailstock force |

KN |

10-300KN |

10-400KN |

10-500KN |

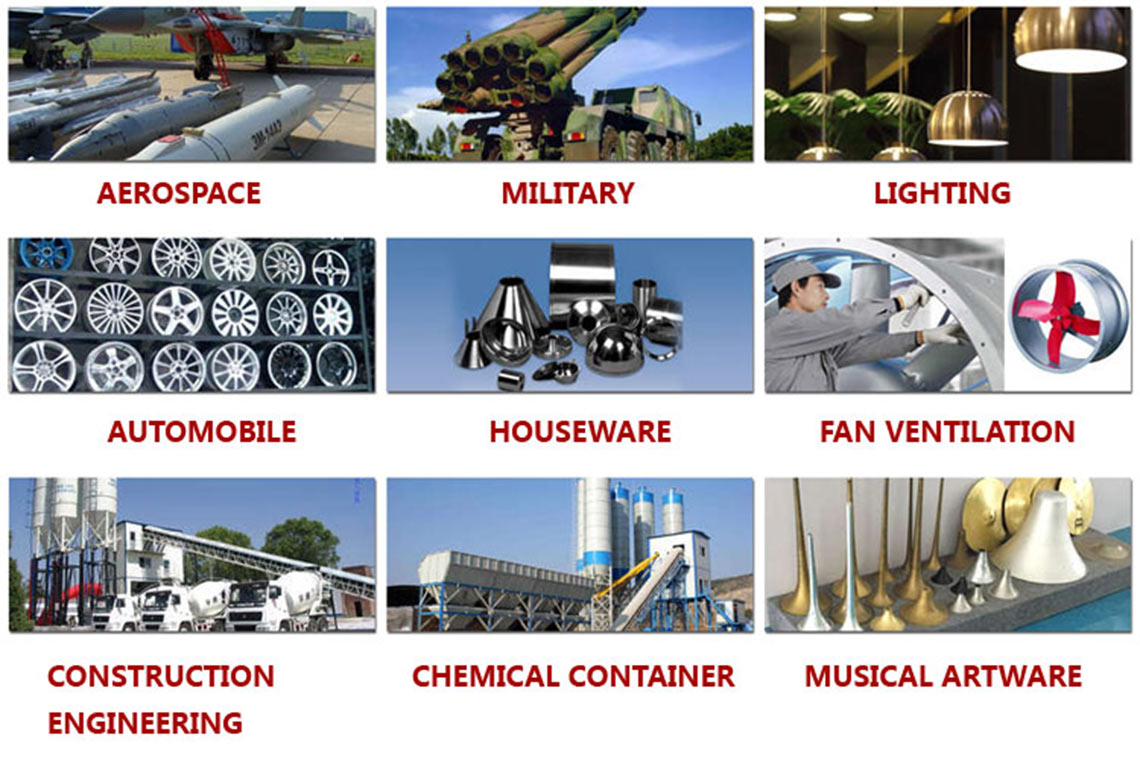

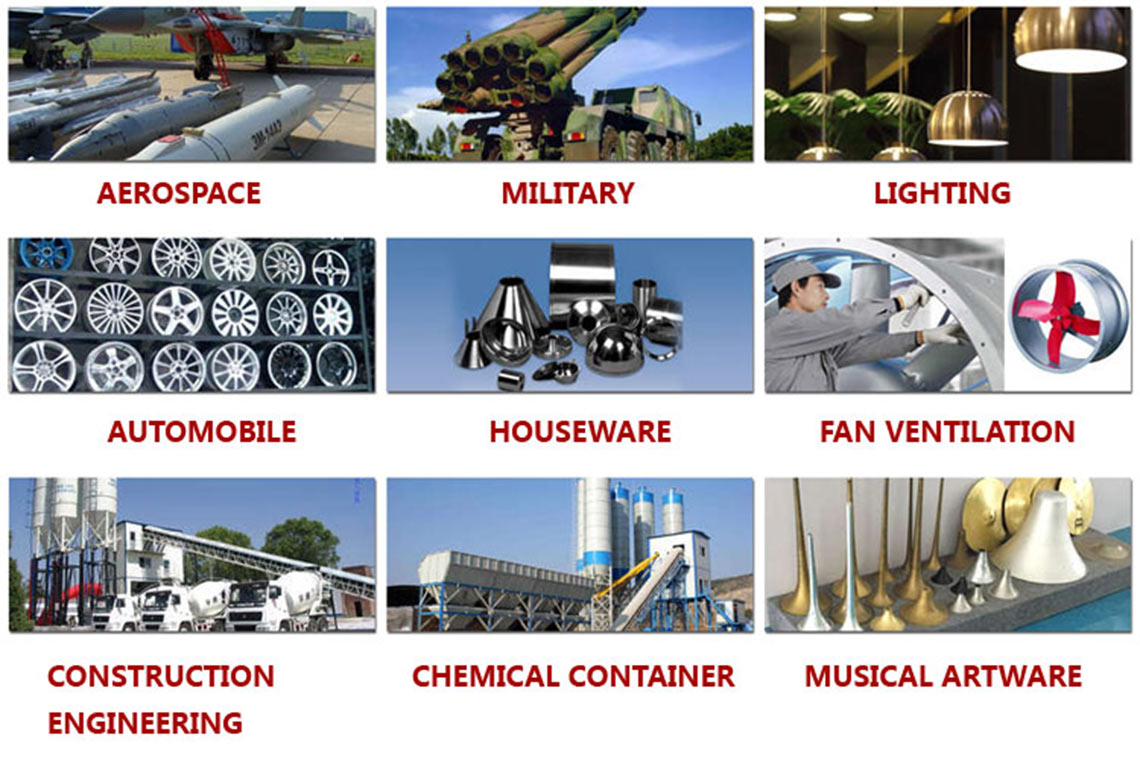

Applications:MILITARY,SPACEFLIGHGT,AVITATION WEAPONS AND OTHER MANUFACTURING INDUSTRIES

-

1.THREE ROLLERS POWER SPINNING

-

2.SYNCHRONIZING SPINNING AND STAGGER SPINNING

-

3.MULTI AXISES/NULTI CHANNEL CNC CONTROL SYSTEM

-

APPLE TO CARBON STEEL ALLOY STEEL,ATAINLESS STEEL,NONFERROUS METAL AND OTHER ALLOY MATERIAL

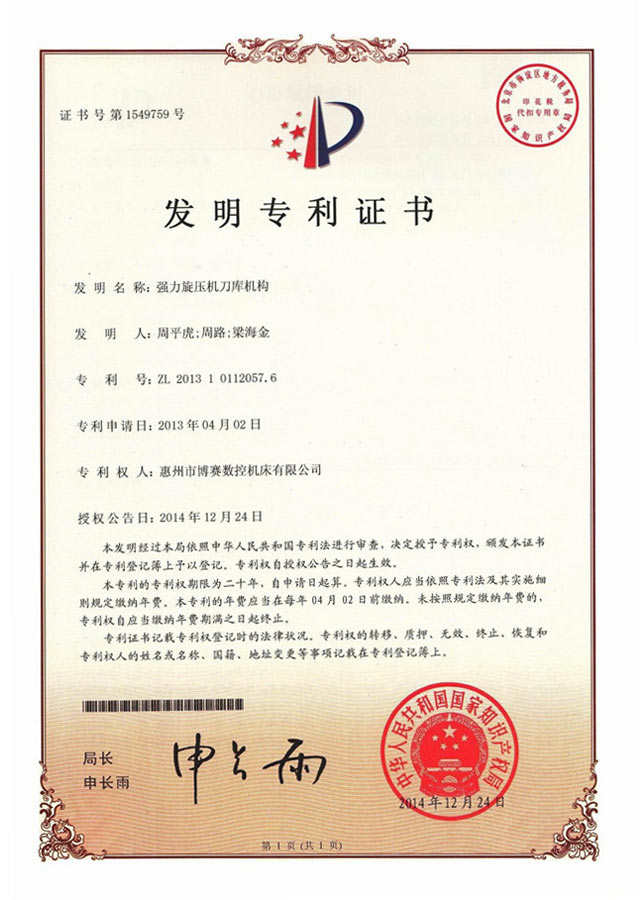

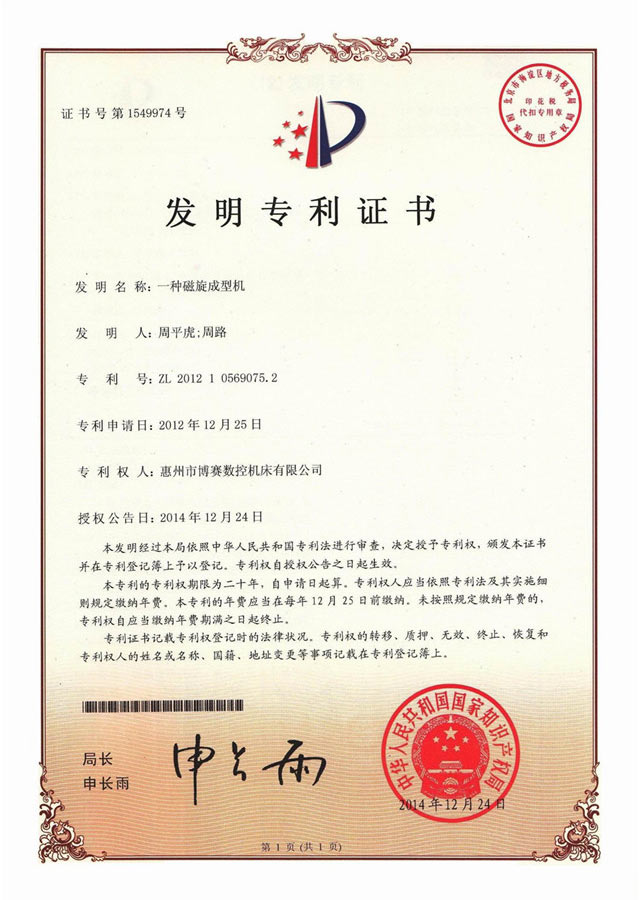

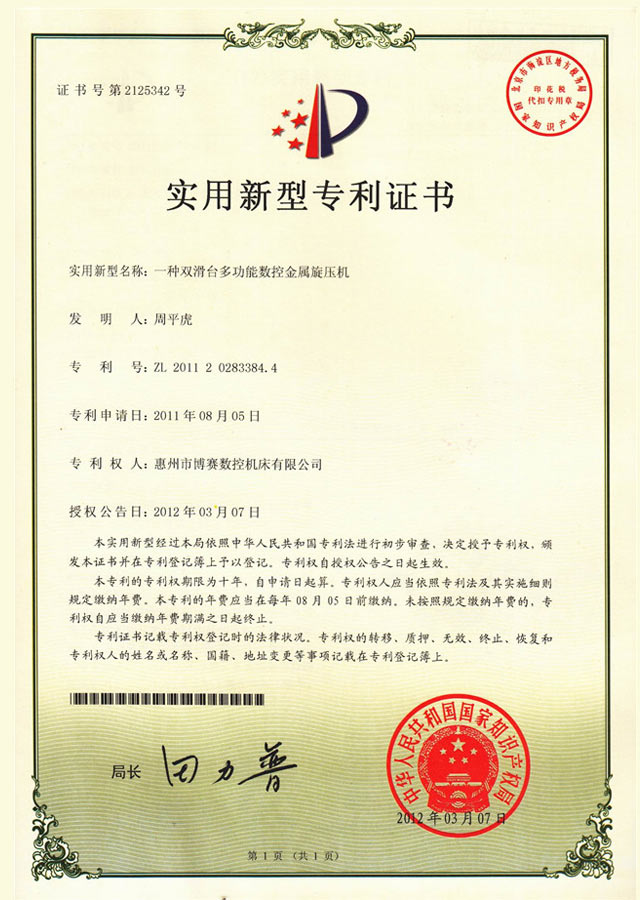

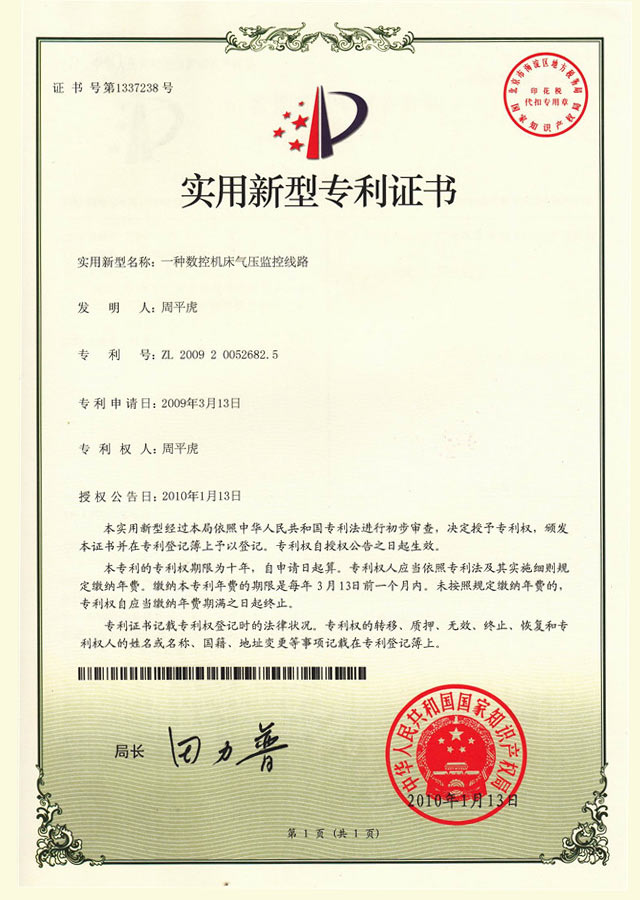

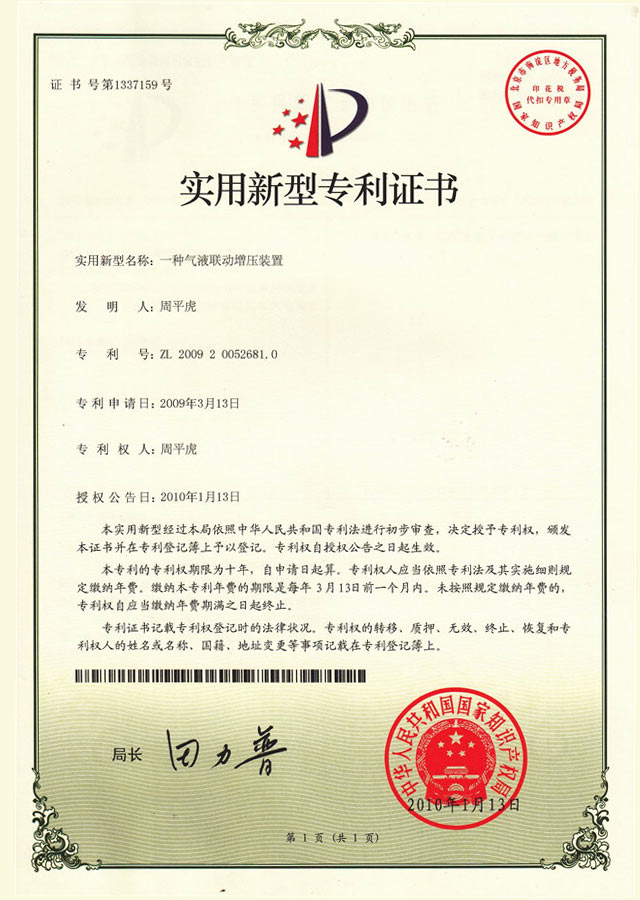

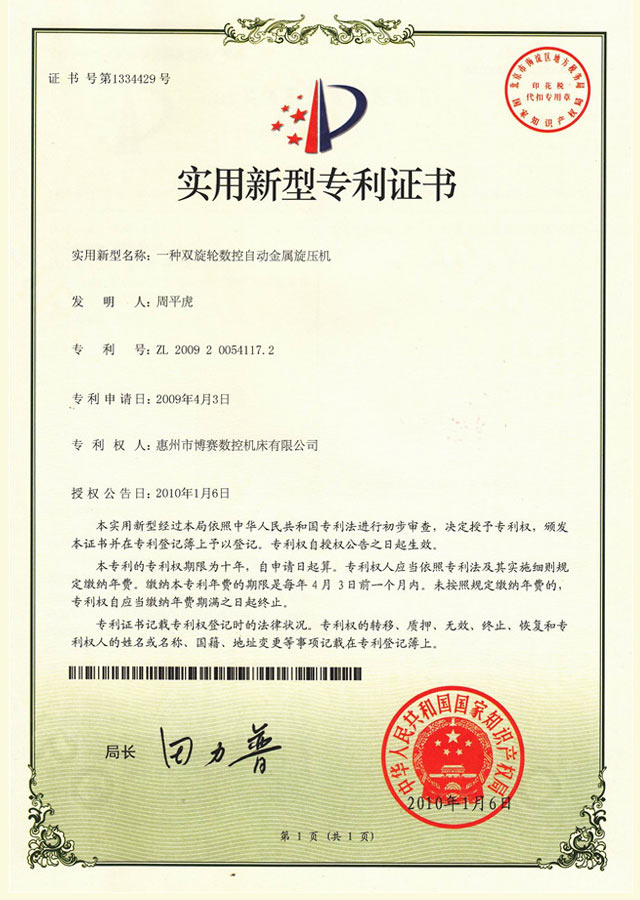

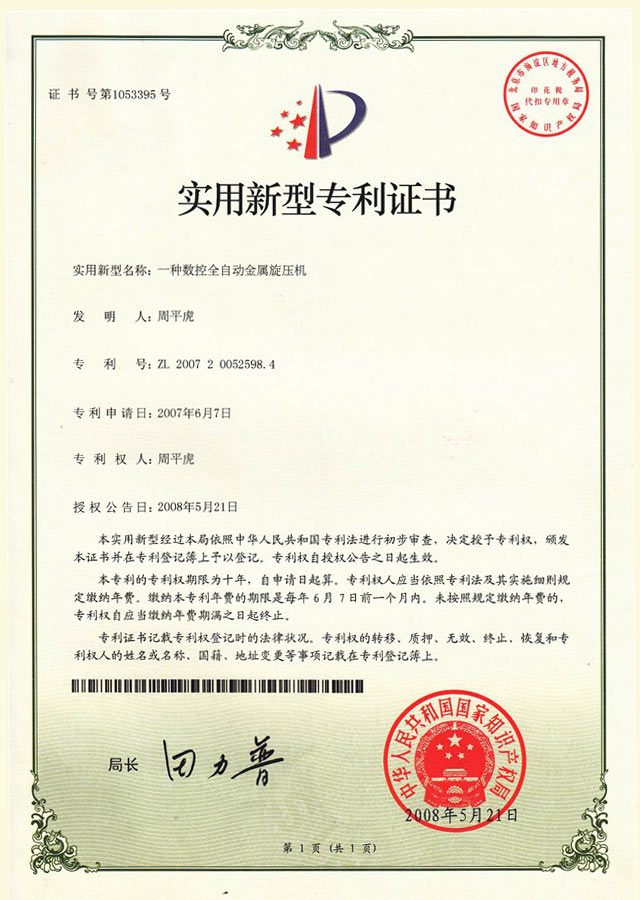

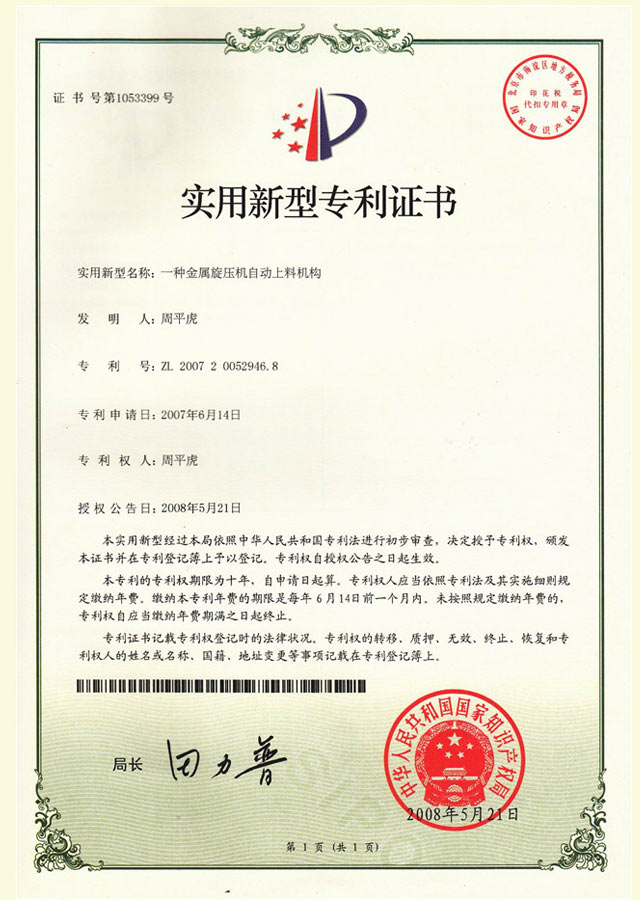

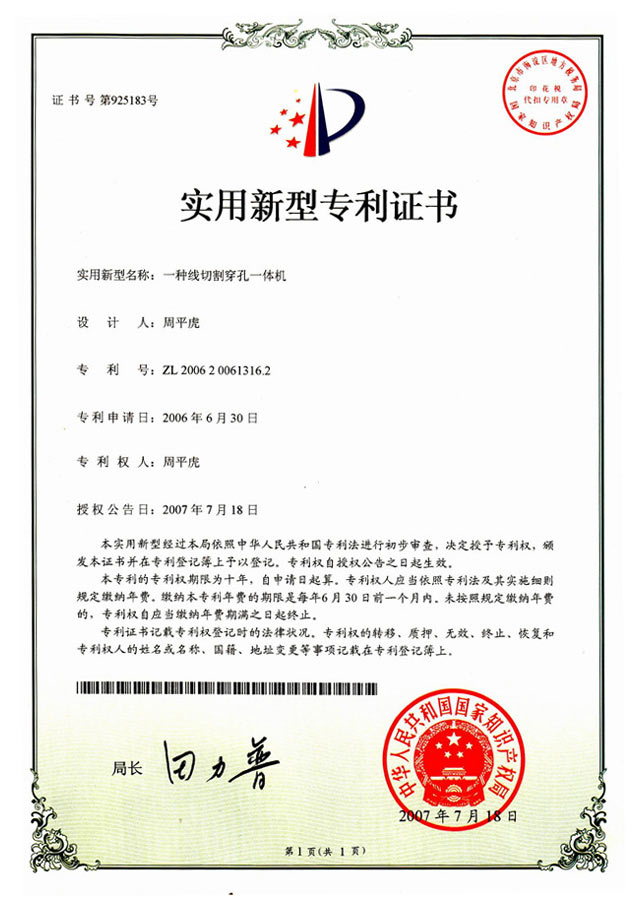

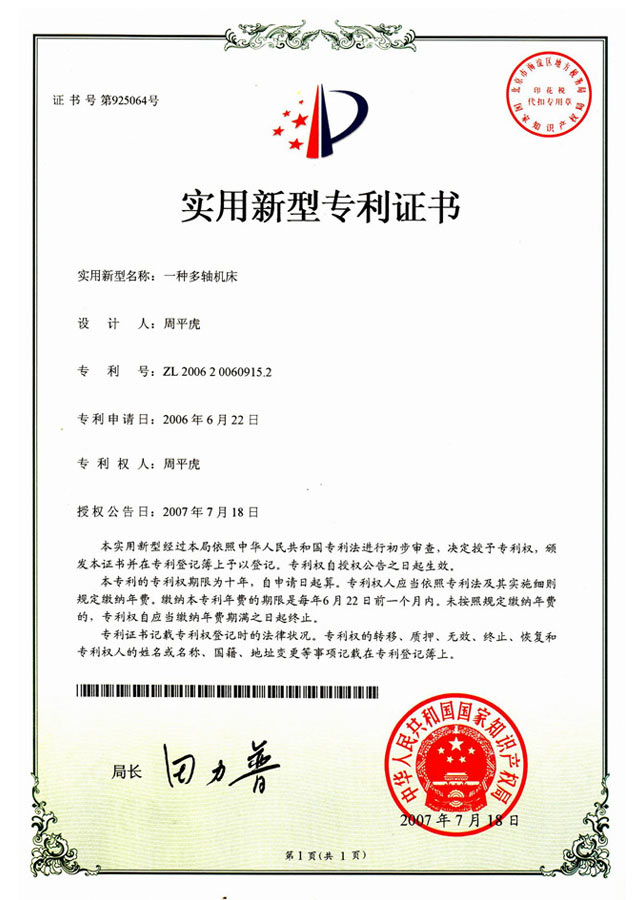

About Prosper

GuangDong Prosper CNC Machine Co.,Ltd is an enterprise of industrialization of new high technology which integrates research center,manufacturing,sales,customer service,and education and training school.After almost 20 years development,Prosper has nowadays owned a fifty thousand square meters operation site.Prosper values the quality of our products and services. We endeavor to provide the products and services of the most competitive advantage to our customers!

Assembly shop

The technology of workshop

The spinning experience pavilion

The technology of workshop

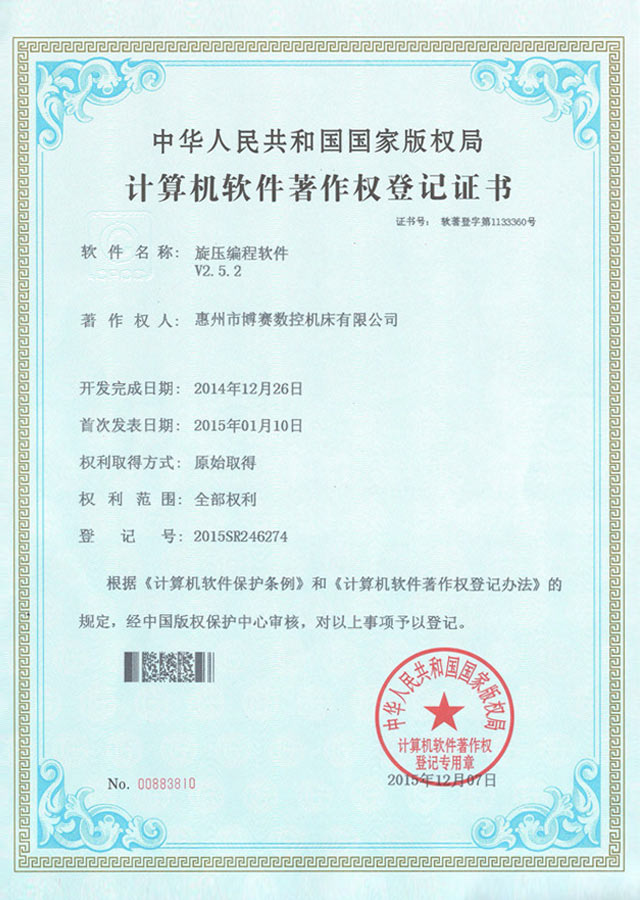

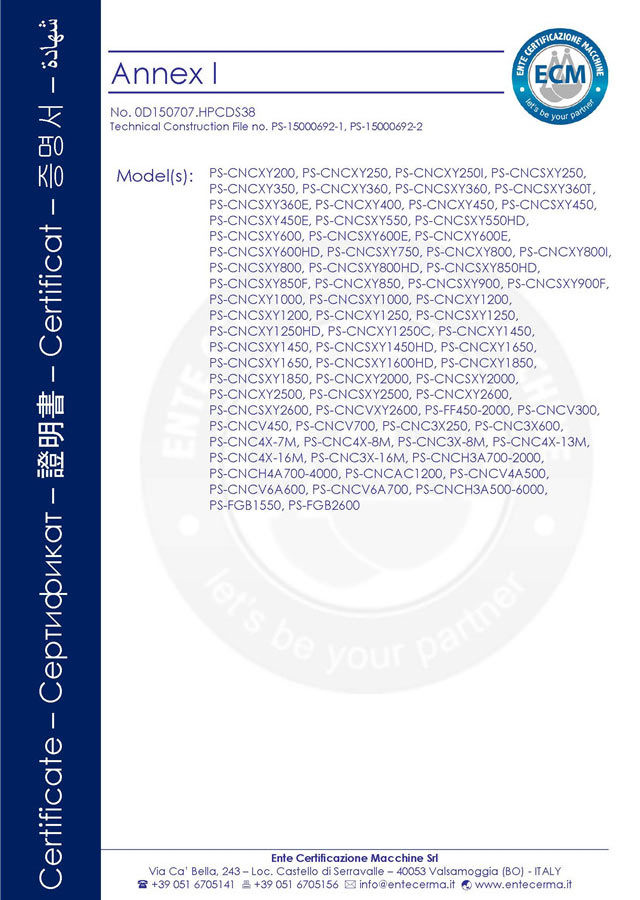

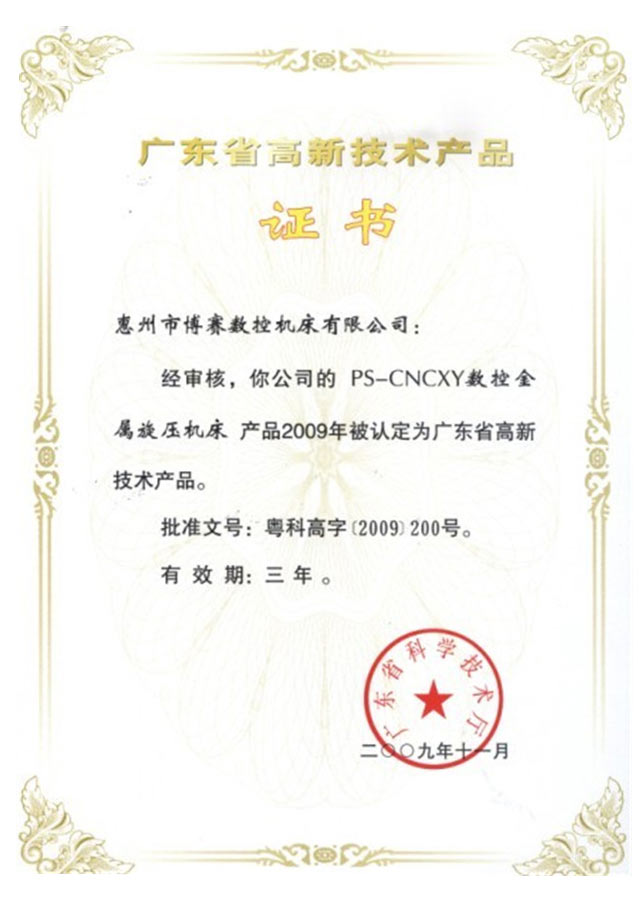

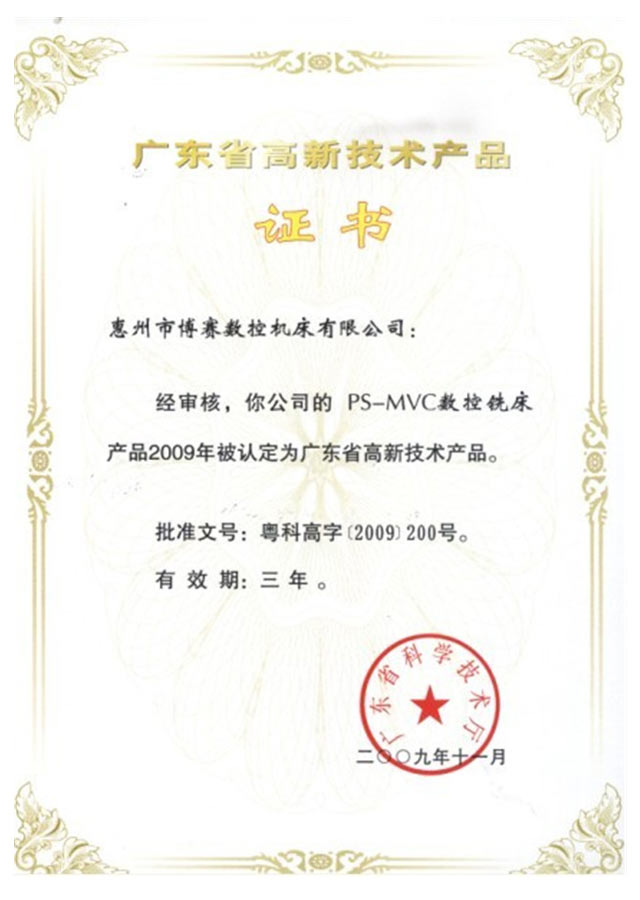

Prosper Core Technology

Application field

Cooperation strategic partner

|

APPLICATION |

|

Casting/Forging Aluminum Wheel |

Casting/Forging Aluminum Wheel |

Casting/Forging Aluminum Wheel |

|

Maximum rotation diameter |

mm |

600 |

720 |

720 |

|

Minimum rotation diameter |

mm |

320 |

410 |

410 |

|

Max double center distance |

mm |

700 |

900 |

1100 |

|

Tool position |

PCS |

2 |

2 |

3 |

|

Longitudinal sliding table stroke |

mm |

460 |

520 |

600 |

|

Transverse sliding table stroke |

mm |

200 |

200 |

200 |

|

Longitudinal sliding table force |

Kn |

250KN*2 |

400 |

400KN*3 |

|

Transverse sliding table force |

KN |

250KN*2 |

400 |

400KN*3 |

|

Main spindle motor power |

KW |

2*100KW |

2*132KW |

2*132KW |

|

Tailstock force |

KN |

10-300KN |

10-400KN |

10-500KN

|

Yes, Once the device is fully active you can switch it between vehicles as you desire.

Yes the OBD unit can be installed in less then 30 seconds.

The devices use the cellular networks to transmit data back to our servers. All the location are obtained using a minimum of 4 satellites . This unit is currently only offered on the AT&T network.

By default the devices do not make any noise. All devices have dim LEDs. You can cover them if needed and it will not impact service.

Every passenger vehicle manufactured since 1996 has an OBD port. Heavy duty trucks manufactured after 2000 are compatible and will have one of two ports. 6 pin J1708 or 9 pin J1962. You will need an adapter or the HD Y cable.