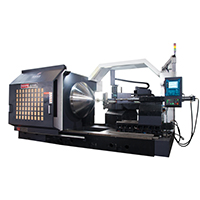

Full functional /High Performance/Large-Diameter CNC Spinning Machine is to meet the need of the spinning products of the industry, especially for the product such as House wares, Light equipment, Engineering, Chemical industry and Aerospace industry, etc.

This series of machine are characterized by their highly efficient and cost-effective benefits they can provide. The spinning process technology can produce various shapes of products, such as in shapes of cylinder, cone, parabola, trumpet and bullet. It not only produces in large quantity, but also carries out the trial-manufacture testing and completes the trimming and rolling of the edge and contraction and extrusion of the products. The machine is suitable for processing of the aluminum alloy plate, steel plate, stainless steel plate and many other materials.

---Spinning of major diameter products

---Spinning of products that not achievable by human labor

---Substitution of drawings/reduction of cost

---Optional dual spindle to reduce mandrel cost

---Excellent cost effective/economical and practical

---High strength cast machine body

---Computerized SIEMENS Numerical Control System

---Spinning tools turret/rollers

---Heave duty guide and ball screw

---High torgue/high speed spindle

---Material centering

---Tool offset

---Digital integrated hydraulic system

---Digital integrated lubrication system

---BA units

---BE units

---Manipulator

---Prosper Spincad programming software

---Second spindle

---Power unit

Applications:Lighting,kitchenware,packings Spinning of major diameter products Spinning of bog thickness material Spinning of products not achievable by human labor Substitution of drawing/reduction of cost Optional dual spindle to reduce mandrel cost Excellent cost...