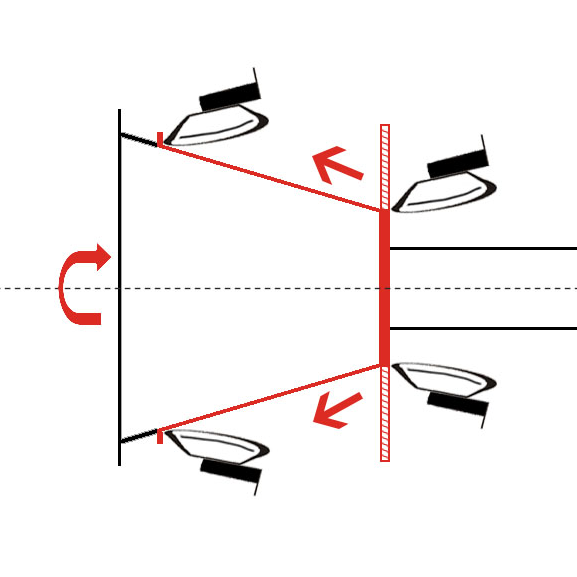

Forced spinning of conical parts, also known as shear spinning, refers to the installation and fixing of sheet or conical blank on the die. When spinning, the spinning roller rotates with the workpiece and die, and the workpiece deforms point by point, which makes the blank reach the required wall thickness and angle. Shear spinning can also be divided into positive spinning and reverse spinning.

In shear spinning, the wall thickness of conical parts (or other special-shaped parts) follows the Law of Sines.It generally takes place in a single and double roller pass involving a deliberate reduction in wall thickness,however without any change in diameter.The forming load and accuracy in different process was discussed,and the right forming scheme was obtained on the bases of the analysis.