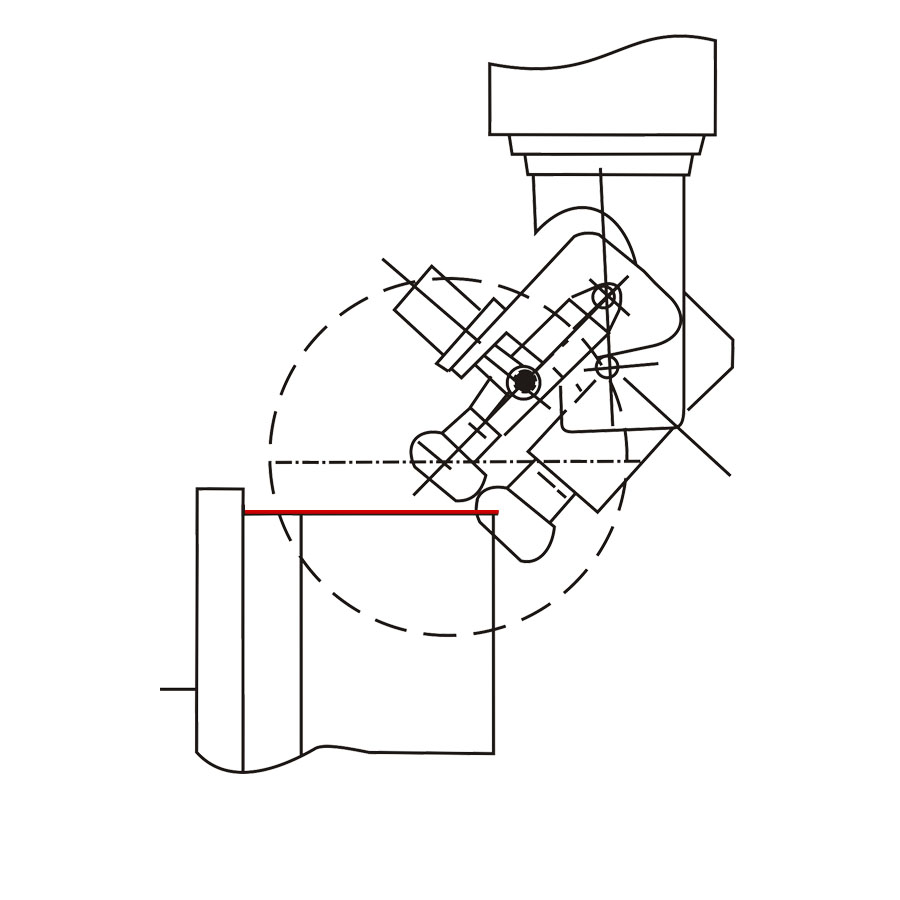

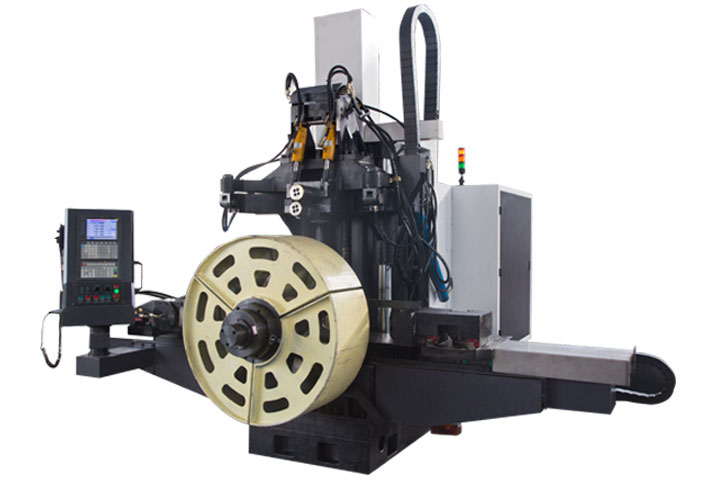

Spinning flanging is a process for flange forming and bell moulding of barrel-shaped products. It holds the edge of barrel-shaped products by two roller.

Through specific angle and spinning clamping force, the product of barrel-shaped products can be flanged at 90 degrees and specific angle, and then trimmed by turning tool can realize the perfect outline.

For spinning flanging, the material quality for ovality of barrel shape and welding should be ensured, which will affect the stability and quality of clamping.