This machine is specially design for the ventilation industry. The machine is suitable for processing of the components for ventilation, modular chimneys, flanging, beading, marking of several pieces

This series of machine has resolved the problems and limitations that exist in the traditional manufacturing method, including the intense work required for manual operation, inconsistency in products, low efficiency in production and the backwardness of the production technology.

We build machines specifically designed for every specific application that our customer needs. All our machines are built after a deep analysis of the customer’s needs making possible to incorporate all the features and accessories required for every specific work.

This machine has introduced the user friendly advanced numerical program-control technology, which enables one person to control several machines at one time. It has largely reduced the cost of production and improved the efficiency and effectiveness, which is the best option for mass production of high quality production.

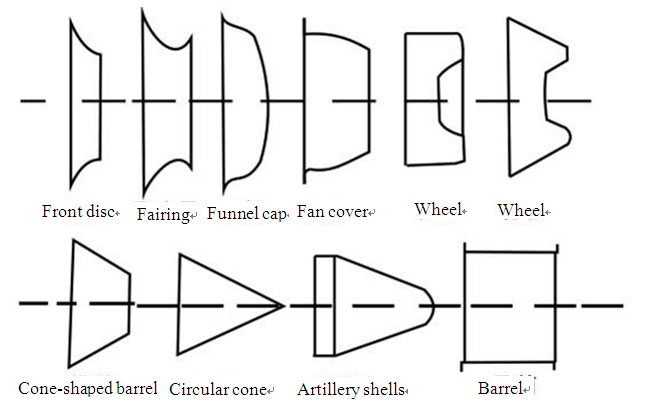

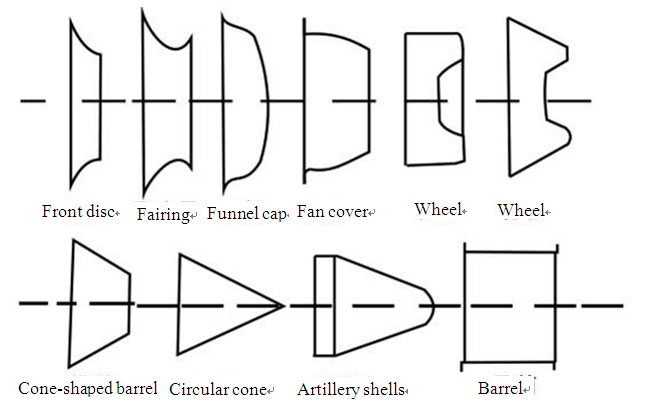

Spinning process is a technology that using one or several rollers to press metal blank(circular plate, seamless or welded tubular, cone blank) in rotation with unit pressure of 25~35MPa, making it gradually produce plastic deformation, finally complete the expected shape and size of the hollow thin-wall rotary body parts. The spinning process includes forming process like extrusion, drawing, rolling and bending.

For the forming of ventilation parts, mainly has 4 points:

1.Simple tooling. Generally only needs a simple mold. The mold material is cheap, which can be used by ordinary cast iron or welded with sheet material. The processing is simple, therefore the cost is low.(Stamping and drawing requires at least one set of die steel, sometimes more than one set of concave and convex die.)

2.After spinning, mechanical strength of the material is significantly improved, so the wall thickness of the parts can be thinner, which saves materials.

3.Achieve overall parts with no welding and beautiful appearance.

4.Spinning equipment has low weight and power consumption, while can process large parts. So it has high cost performance.