Spinning Software

The close cooperation with our customers in software development ensures an intuitive and practical user experience. Individual features can be added to different production steps, individually configured and optionally executed. The innovative software features leave room for endless possibilities for individuals and make the entry into professional spinning much easier, especially for new customers without much programming experience.

The rapid prototyping “spinning to go” ensures the rapid development of prototypes and sample parts. Small lot sizes, sample parts, and demonstration pieces can be implemented without long set-up times.

System Software Standard Configuration:

-

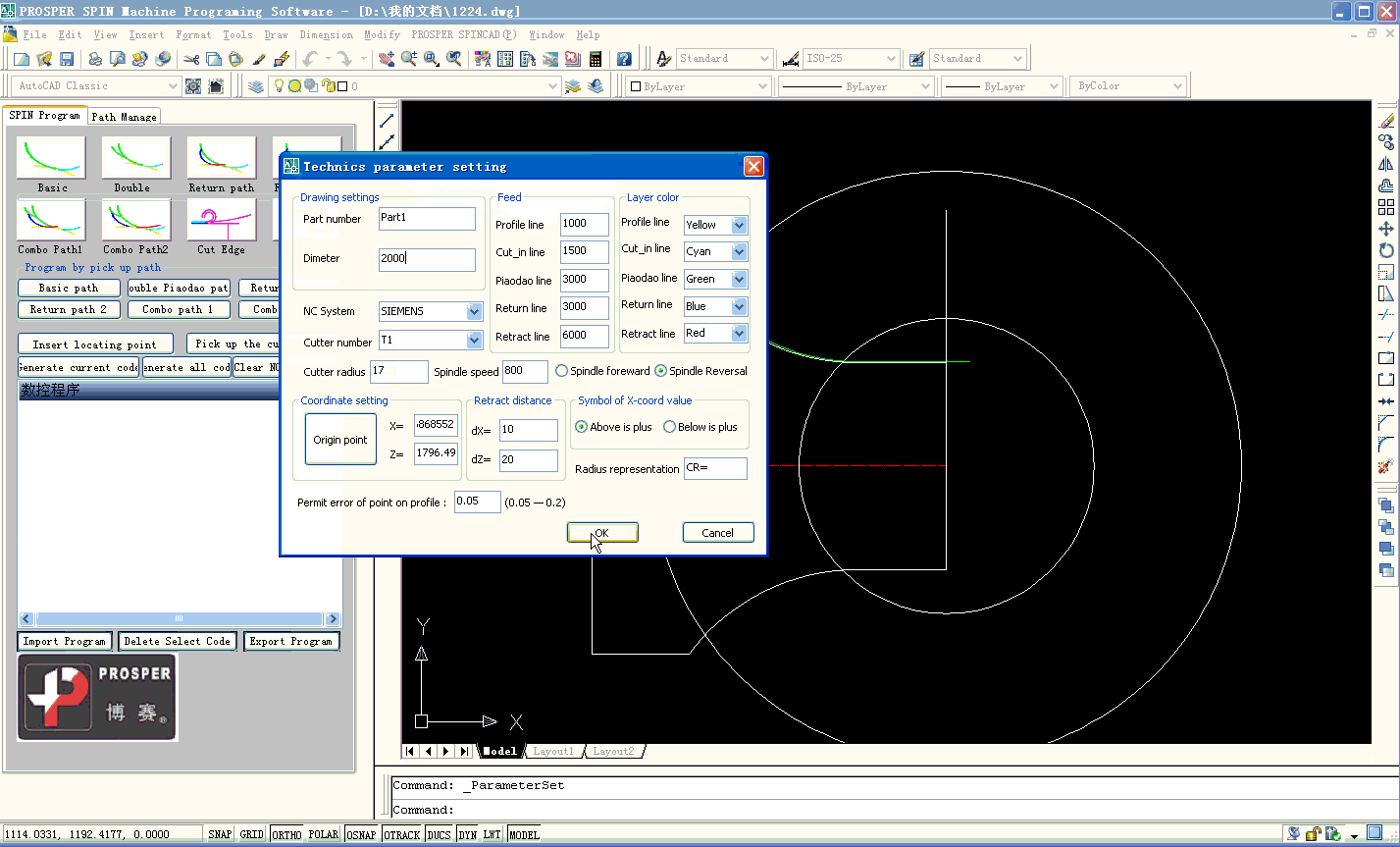

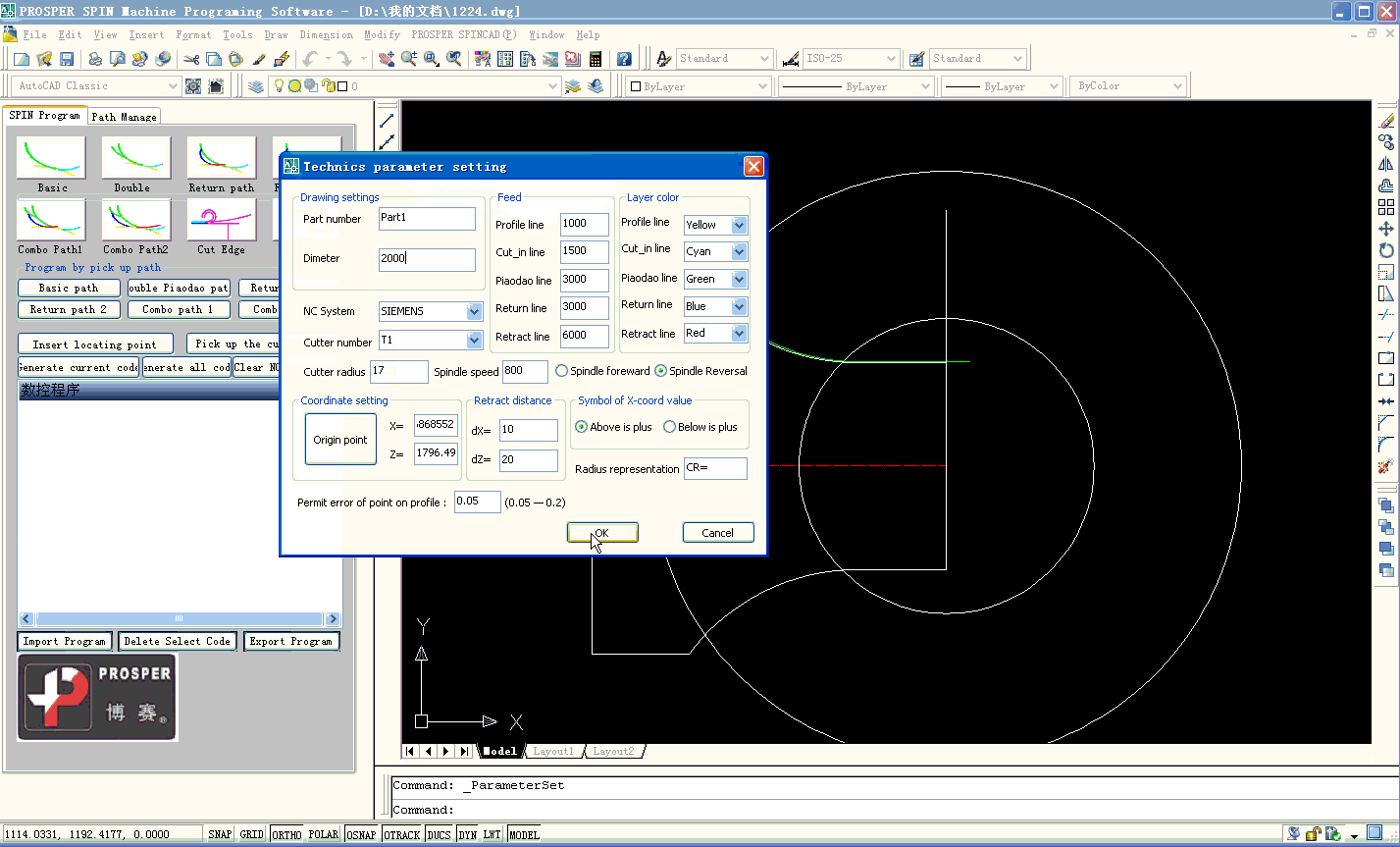

(1) Spinning Path Editing Assistant Software MASTCAM 9.1

-

(2) AUTOCAD (DWG/DXF format)

-

(3) PROSPER SPIN V2.53/V5.0 Spinning Programming Automatic Software (Graphic Automatic Conversion G Code)

-

(4) Spinning Path Simulation Software CIMCO Edit4 (Program Path Display)

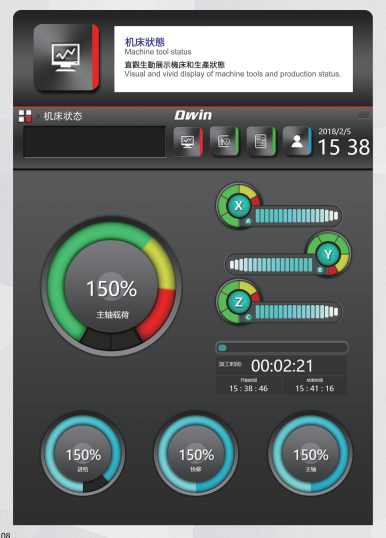

Metal spinning process in today’s design as CAD/CAM forming technology makes the production technically flexible with reduced tooling cost. Prosper offer full sets of programming softwares as well as its training course for customer free of charge(the roller path editing software MASTCAM, mold and path road drawing software AUTOCAD, spinning path simulation software CIMCOEdit4, PROSPER G transcoder, PROSPER SPINCAD) etc. PROSPER will upgrade all software free of charge. And free training for all new development software.

Prosper SpinCAD software offer lifetime free updates and spinning database update.