Technical Data:

|

Parameter |

PS-CNCXY3000 |

PS-CNCXY4000 |

PS-CNCXY5000 |

|

Max sheet diameter |

3000mm |

4000mm |

5000mm |

|

Max center distance |

1800mm |

2500mm |

3500mm |

|

Max X axis travel |

800mm |

900mm |

1000mm |

|

Max Z axis travel |

1500mm |

2000mm |

3000mm |

|

Main spindle motor |

110kw(servo) |

155kw (servo) |

315kw (servo) |

|

Spindle limit speed |

600rpm |

600rpm |

600rpm |

|

Spindle connecting size |

A2-15 |

A2-20 |

A2-20 |

|

Tailstock force |

150kn |

150kn |

200kn |

|

Tailstock travel |

600+600mm |

800+1000mm |

1000+1500mm |

|

Tool sets |

4 |

4 |

4 |

|

Hydraulic Station Power |

15 kw |

15--30kw |

30--100kw |

|

Maximum thrust of feed shaft |

150kn--300kn |

150kn--600kn |

300kn--1000kn |

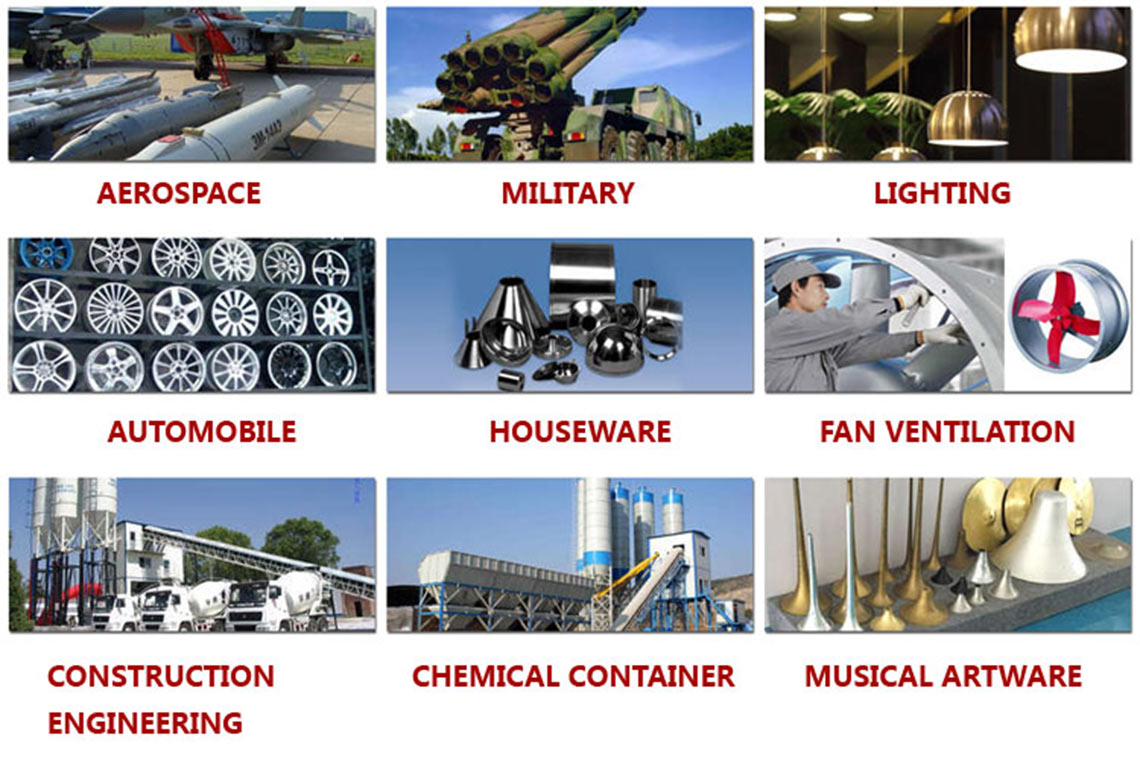

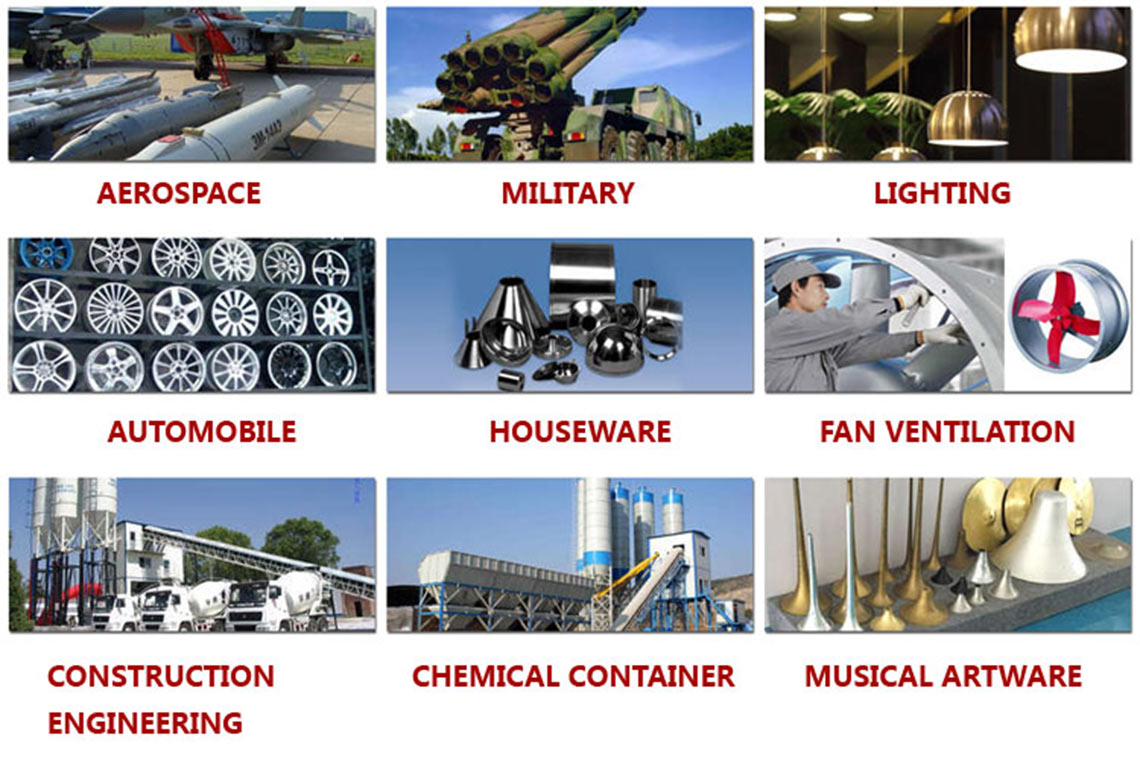

Applications:MILITARY,SPACEFLIGHGT,AVITATION WEAPONS AND OTHER MANUFACTURING INDUSTRIES

-

1.THREE ROLLERS POWER SPINNING

-

2.SYNCHRONIZING SPINNING AND STAGGER SPINNING

-

3.MULTI AXISES/NULTI CHANNEL CNC CONTROL SYSTEM

-

APPLE TO CARBON STEEL ALLOY STEEL,ATAINLESS STEEL,NONFERROUS METAL AND OTHER ALLOY MATERIAL

About Prosper

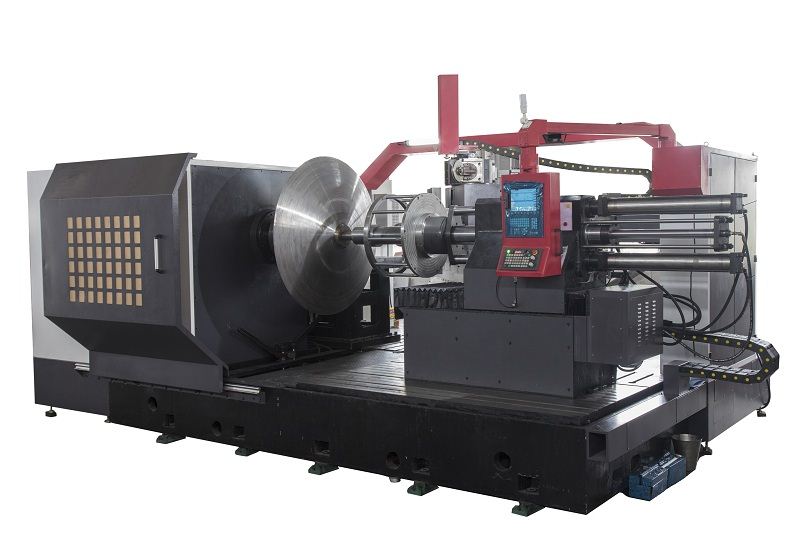

GuangDong Prosper CNC Machine Co.,Ltd is an enterprise of industrialization of new high technology which integrates research center,manufacturing,sales,customer service,and education and training school.After almost 20 years development,Prosper has nowadays owned a fifty thousand square meters operation site.Prosper values the quality of our products and services. We endeavor to provide the products and services of the most competitive advantage to our customers!

Assembly shop

The technology of workshop

The spinning experience pavilion

The technology of workshop

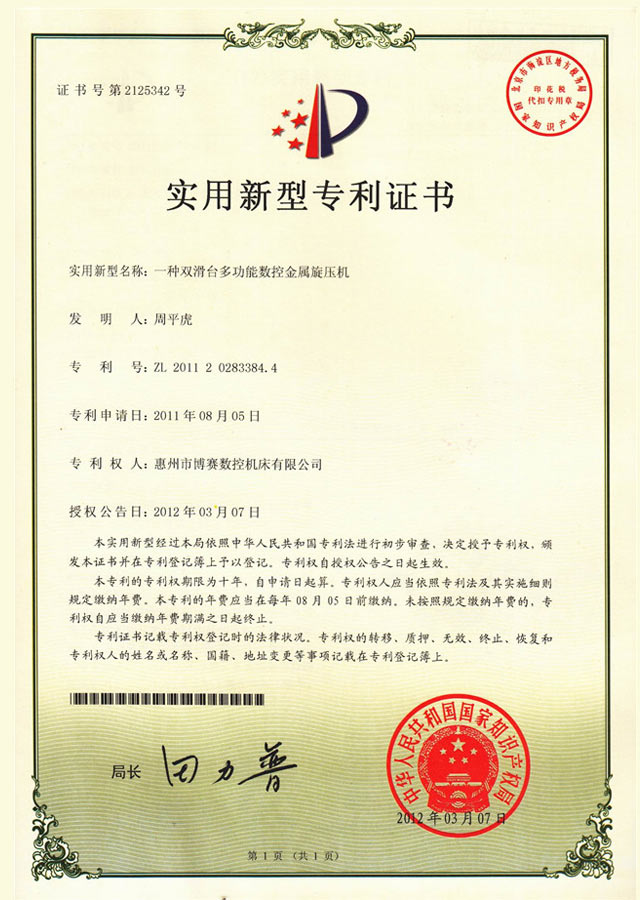

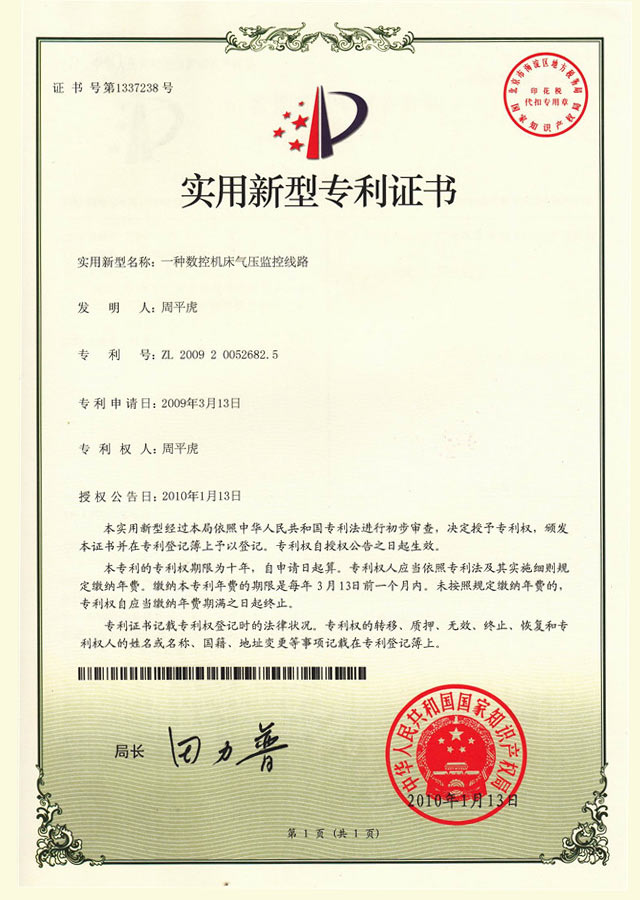

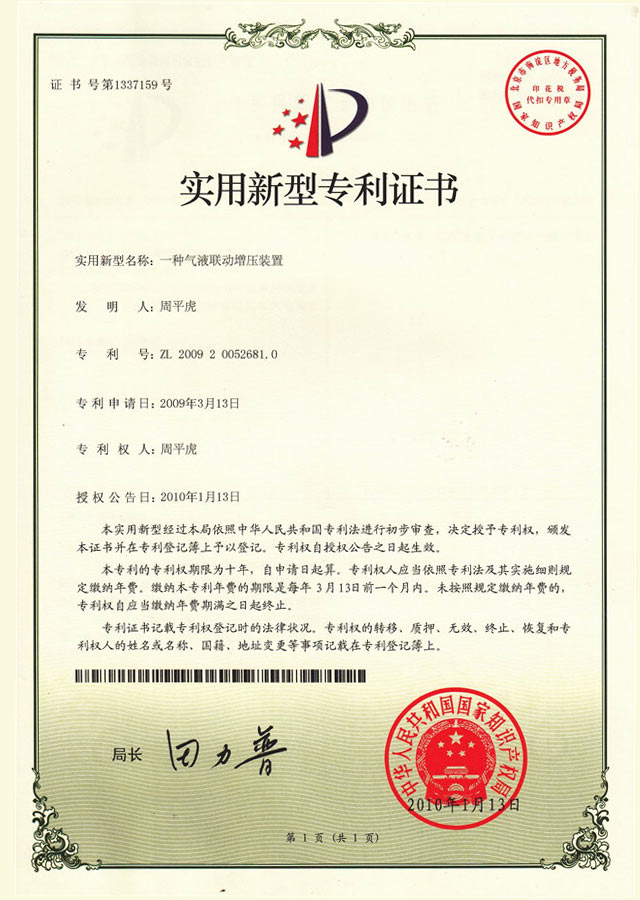

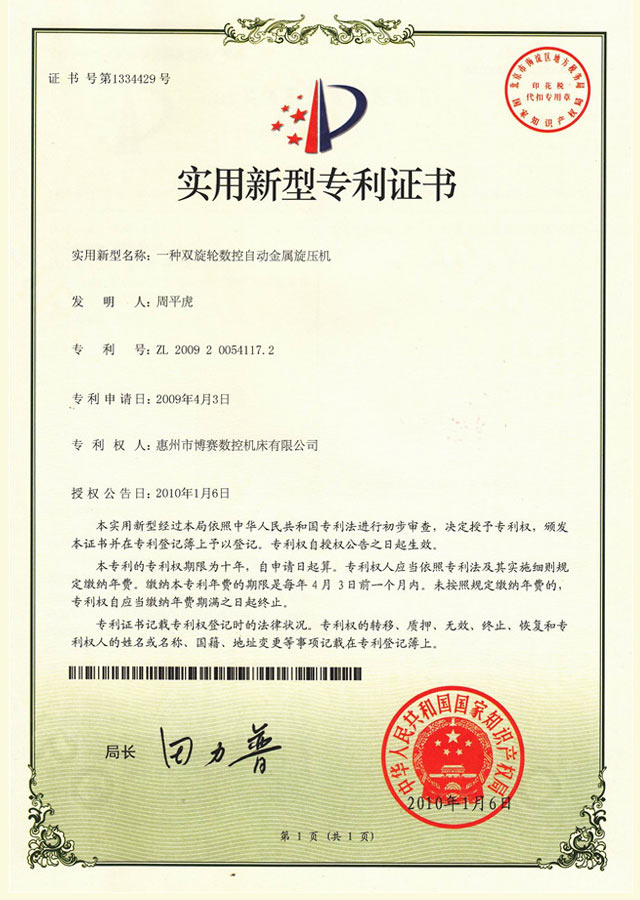

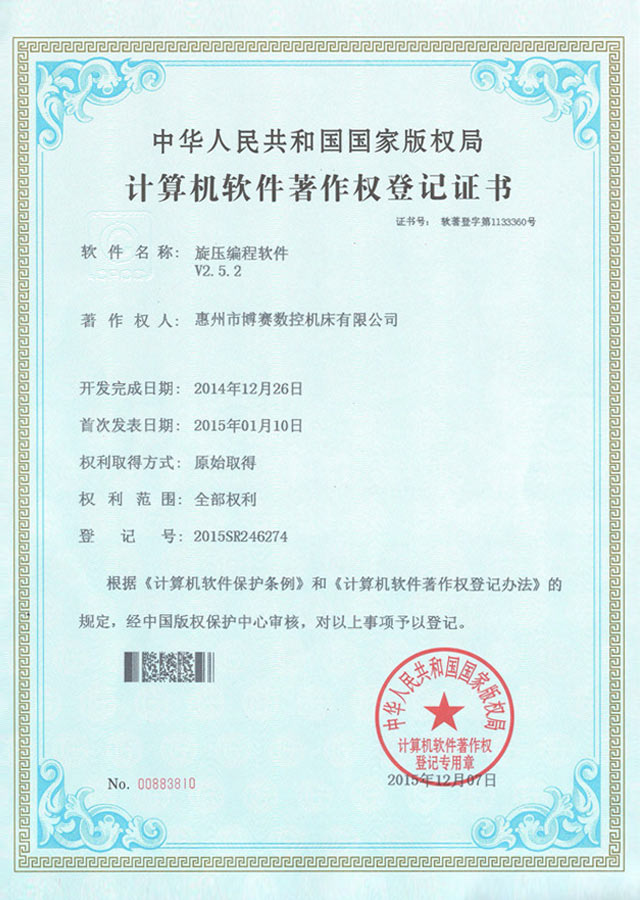

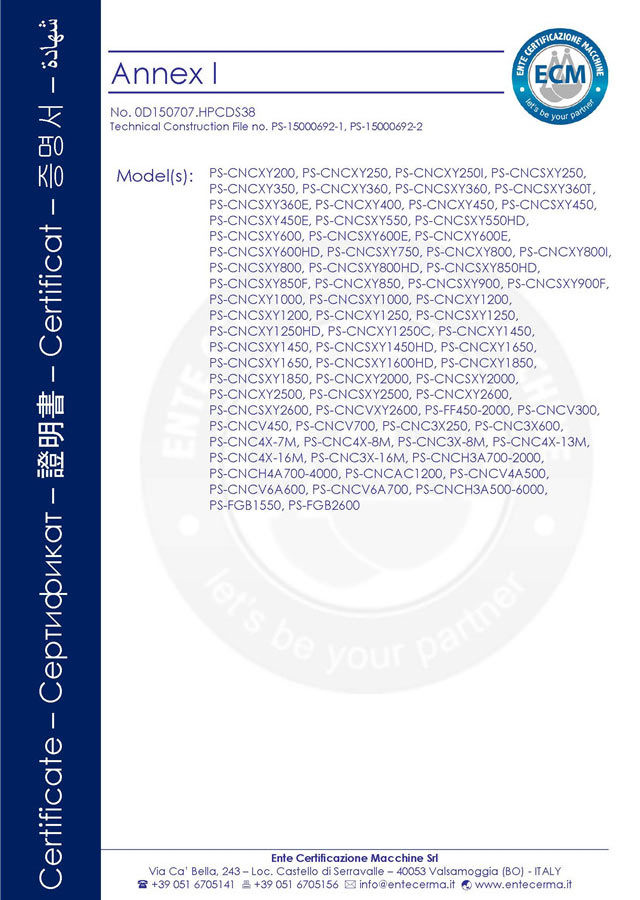

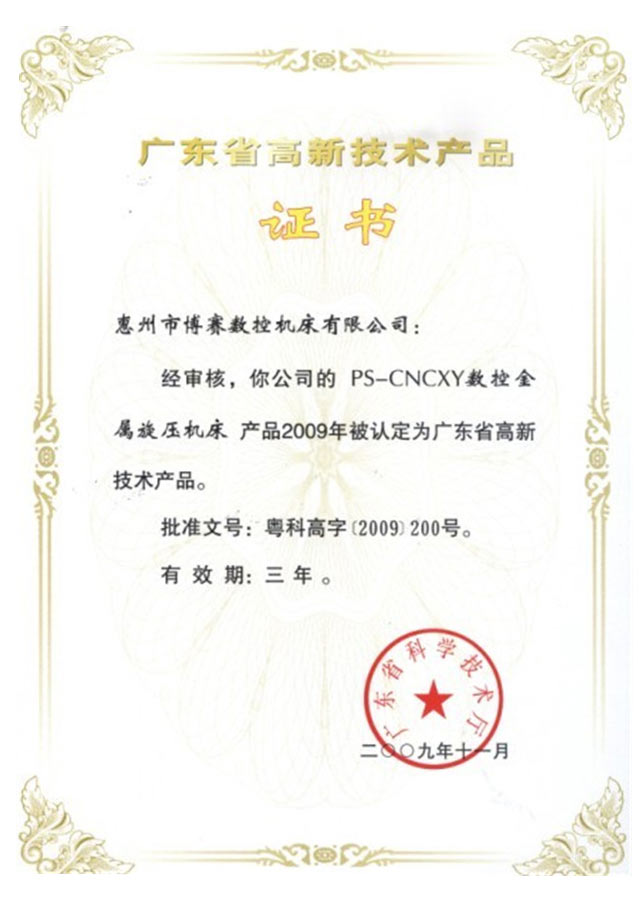

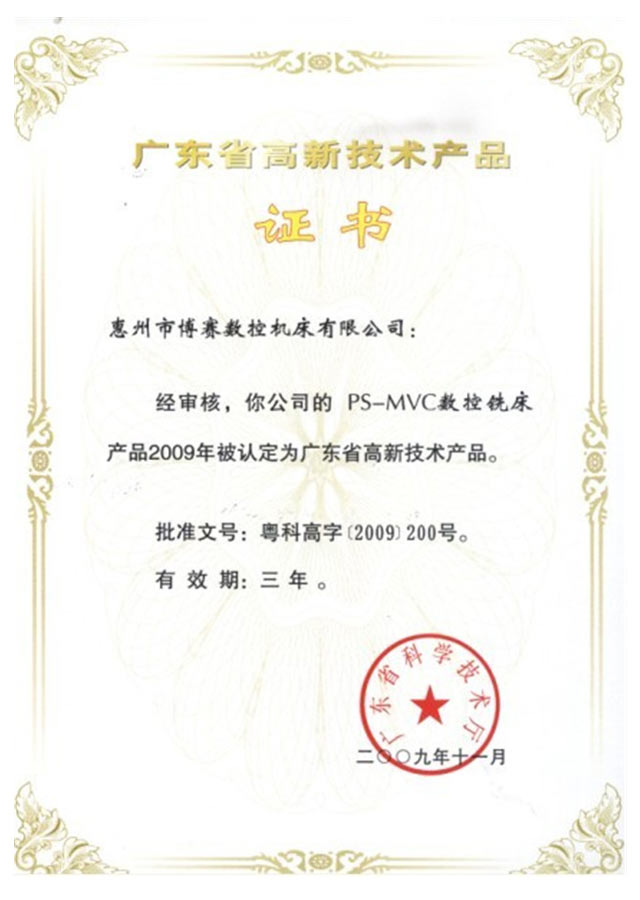

Prosper Core Technology

Application field

Cooperation strategic partner