This series of machines are characterized by their highly efficient and cost-effective benefits

Best spinning solution for small to medium diameter/thickness product Excellent cost effective/economical practical High stability/efficiency Reduce cost of human labor/higt rate of return Technical

High strength cast machine body

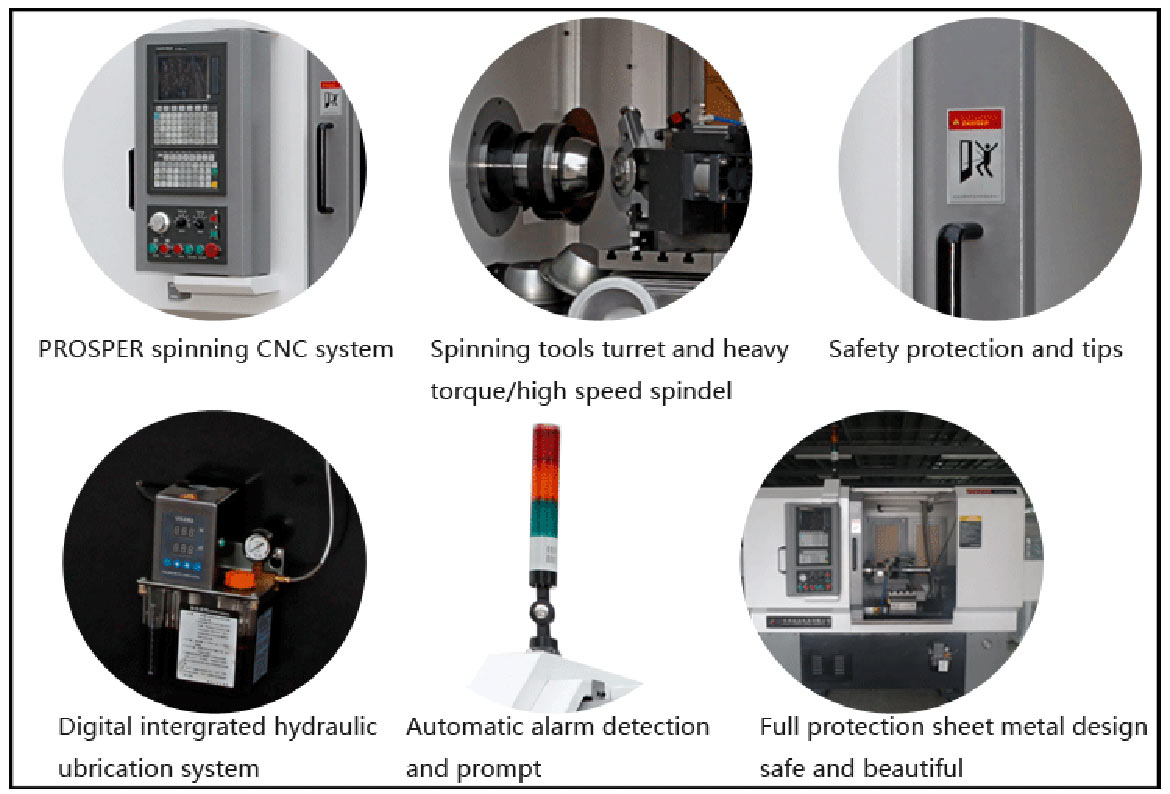

Computerized SIEMENS Numerical Control System

Heave duty guide and ball screw

High torgue/high speed spindle

Material centering

Tool offset

Digital integrated hydraulic system

Digital integrated lubrication system

BA units

Manipulator

Surface treatment tools

Surface Finger tools

Prosper Spincad programming software

Technical Data:

|

Parameter |

Unit |

PS-CNCXY250 |

|

Workpiece Diameter |

mm |

300 |

|

Main spindel power |

Km |

3.7KW |

|

Z axis travel |

mm |

300 |

|

X axis travel |

mm |

380 |

|

Main spindel speed |

rpm |

4000 |

|

Tailstock force |

Kn |

10 |

|

Tailstock travel |

mm |

300 |

|

Tools positions |

|

2+2 |

|

AI/CU Appx.thickness |

mm |

0.5-2 |

|

Steel Appx.thickness |

mm |

0.5-1.5 |

|

S/S Appx.thickness |

mm |

0.5-0.8 |

Applications:Lightings、metal art crafts、hardwares

Best spinning solution for small to medium diameter/thickness product

Excellent cost effective/economical practical

High Efficiency/High stability

Match With automatic material loading system

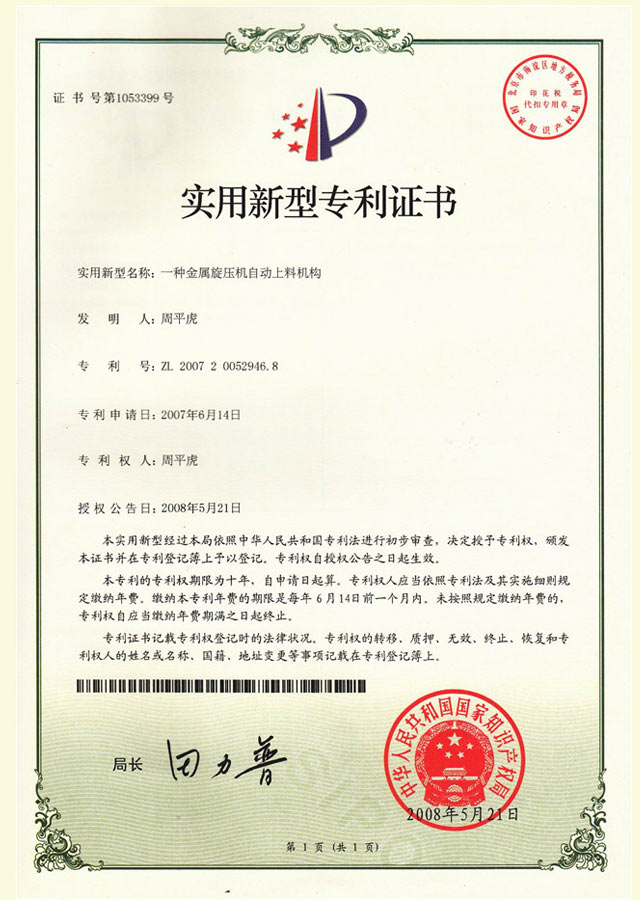

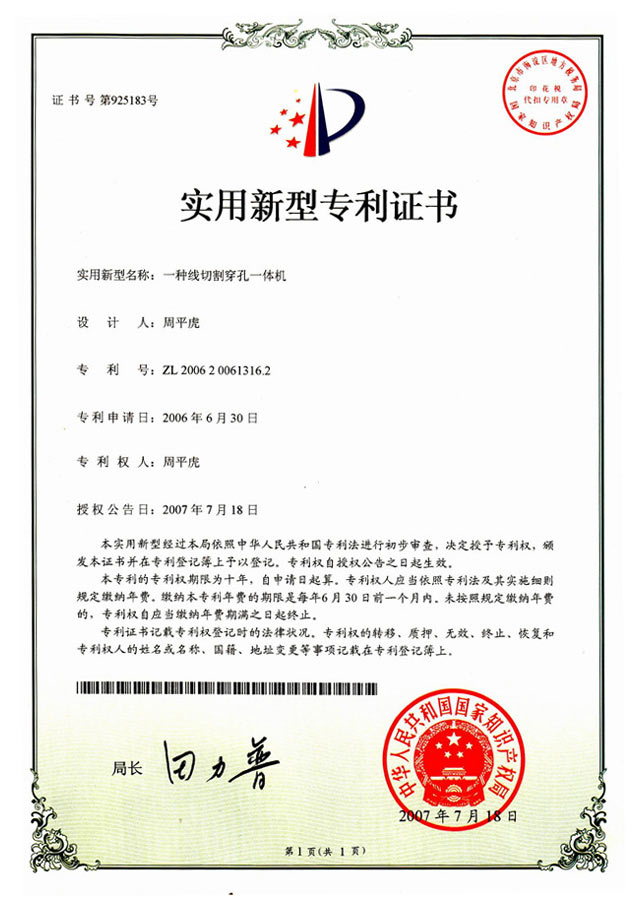

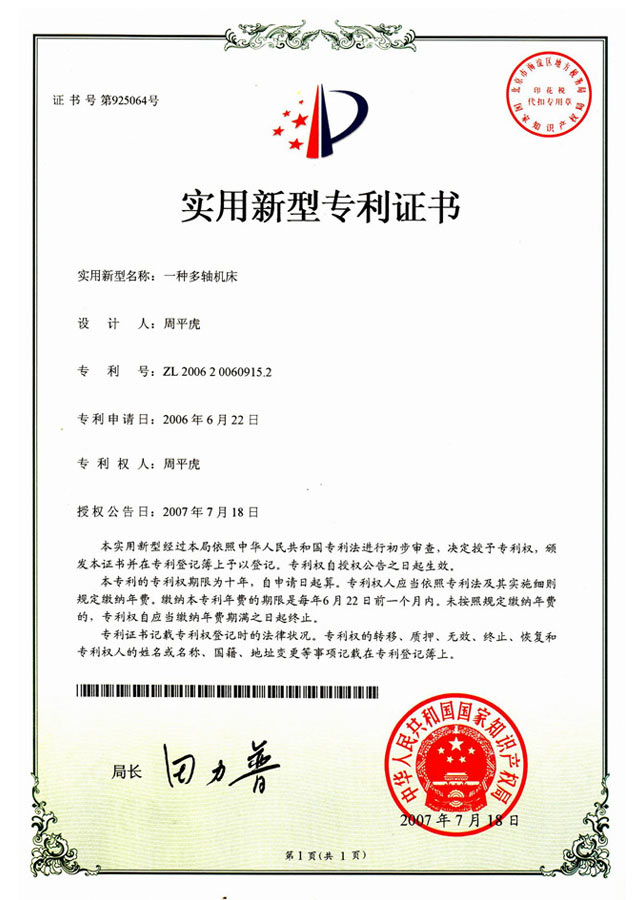

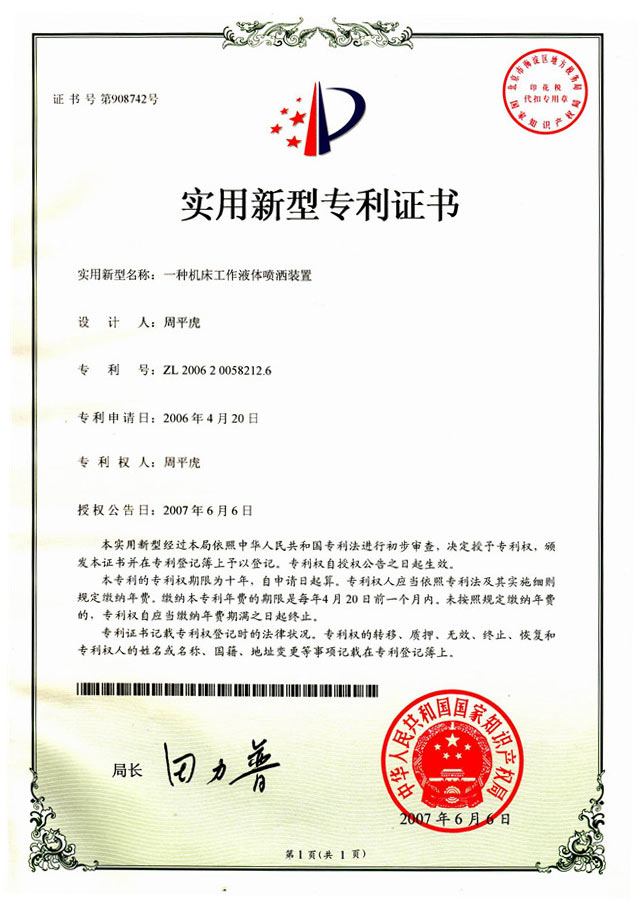

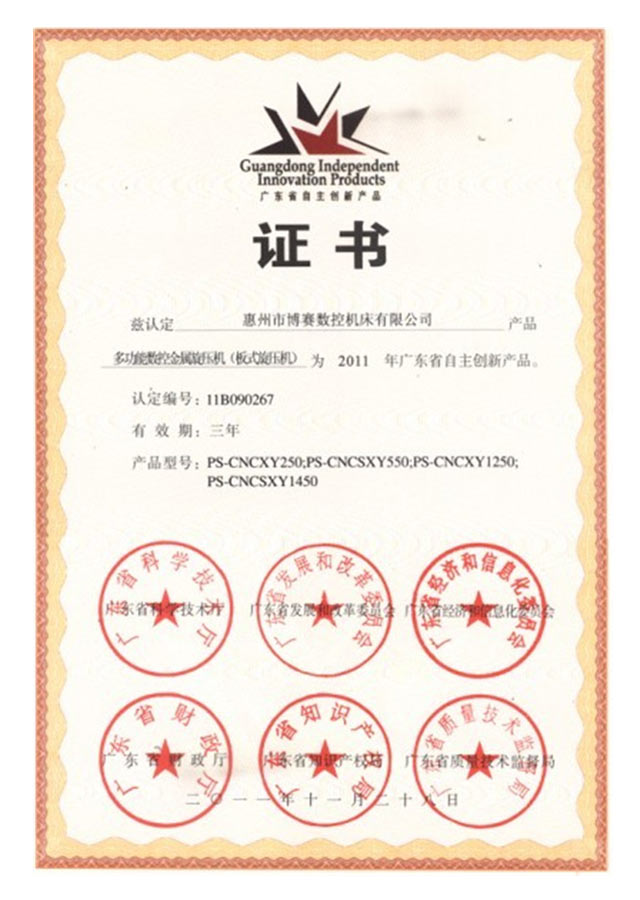

About Prosper

Huizhou Prosper CNC Machine Co.,Ltd is an enterprise of industrialization of new high technology which integrates research center,manufacturing,sales,customer service,and education and training school.After almost 20 years development,Prosper has nowadays owned a fifty thousand square meters operation site.Prosper values the quality of our products and services. We endeavor to provide the products and services of the most competitive advantage to our customers!

Assembly shop

The technology of workshop

The spinning experience pavilion

The technology of workshop

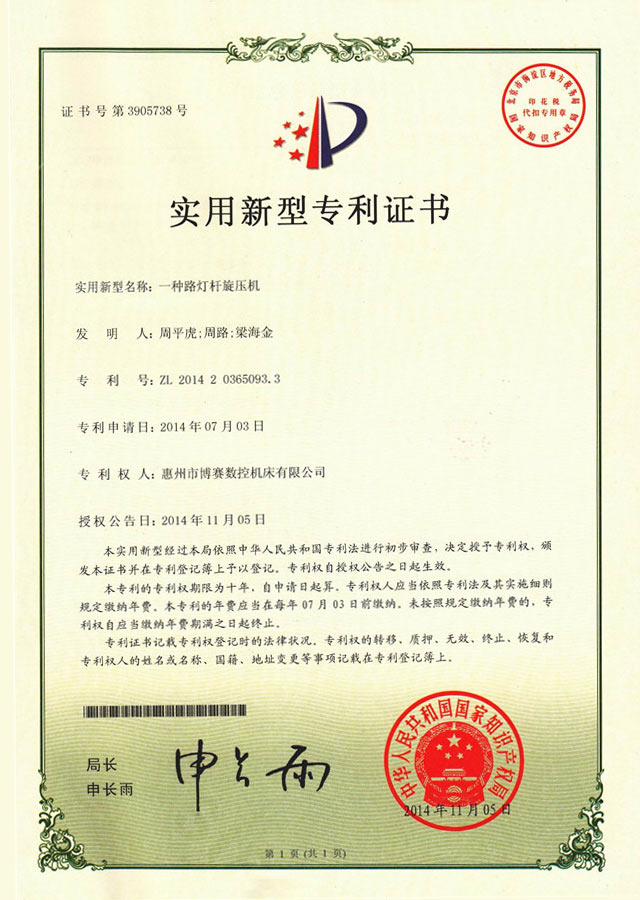

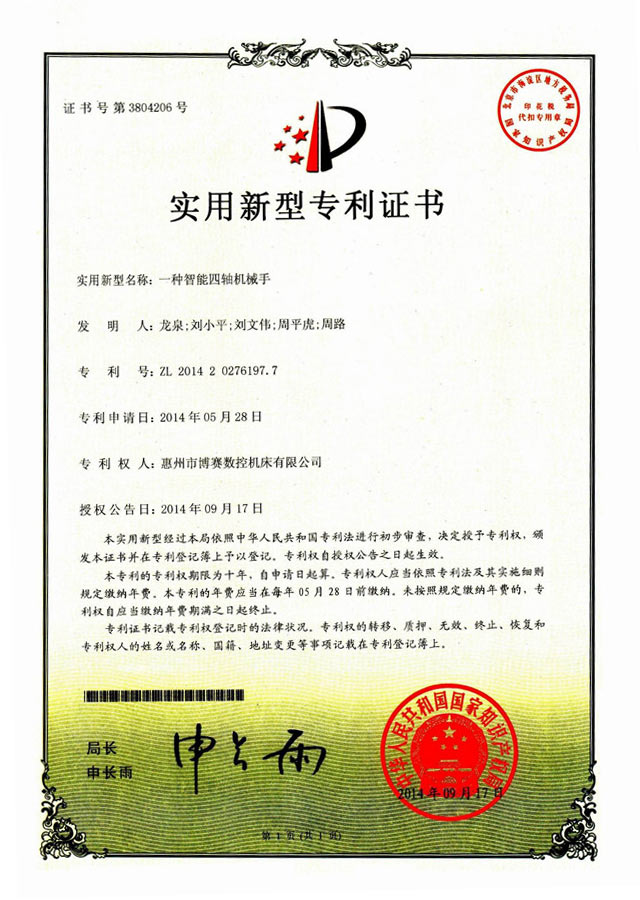

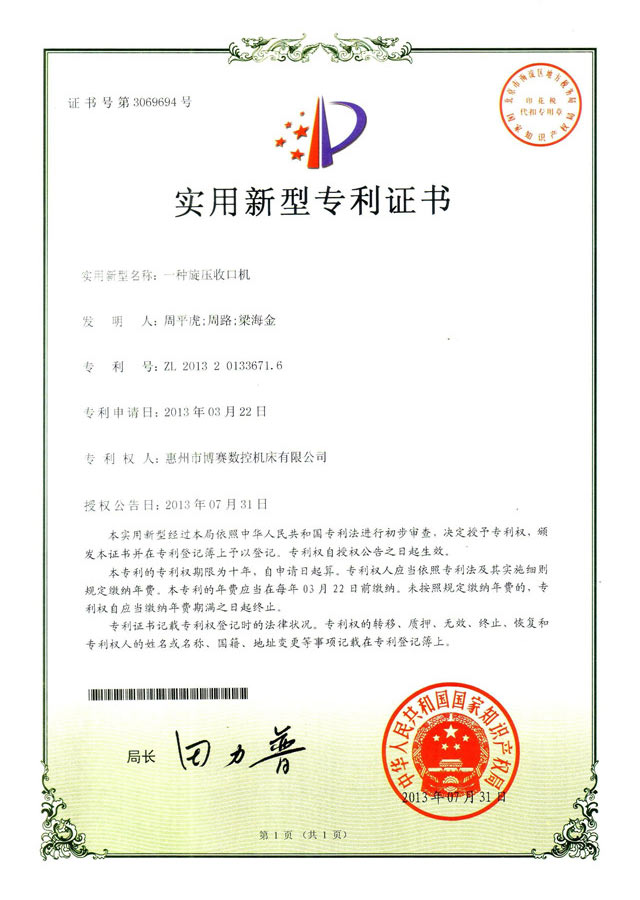

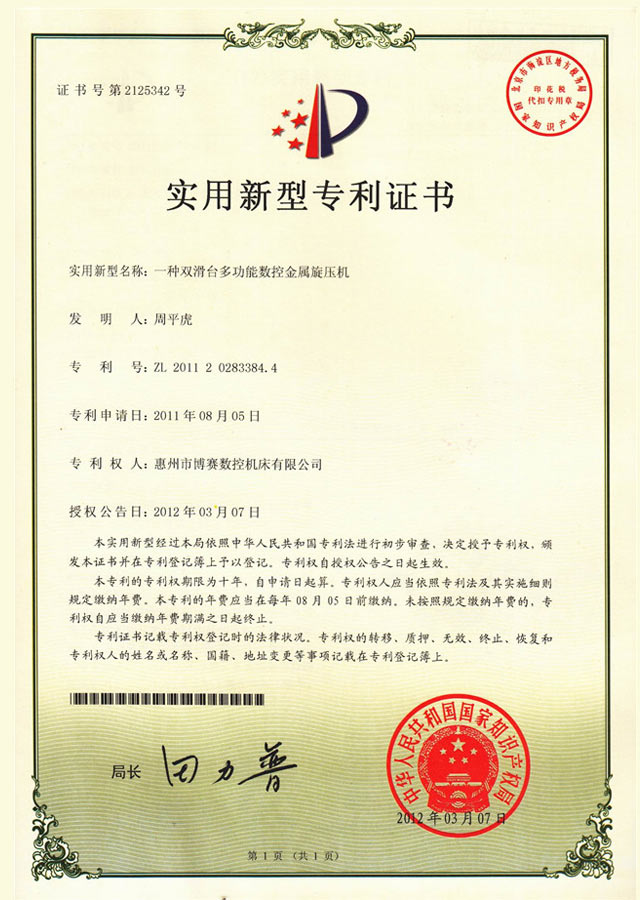

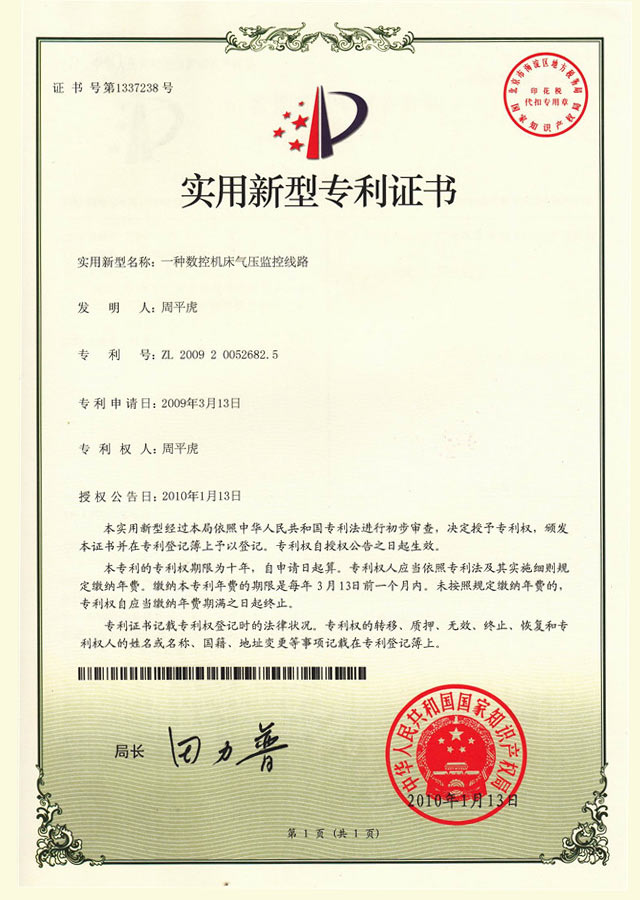

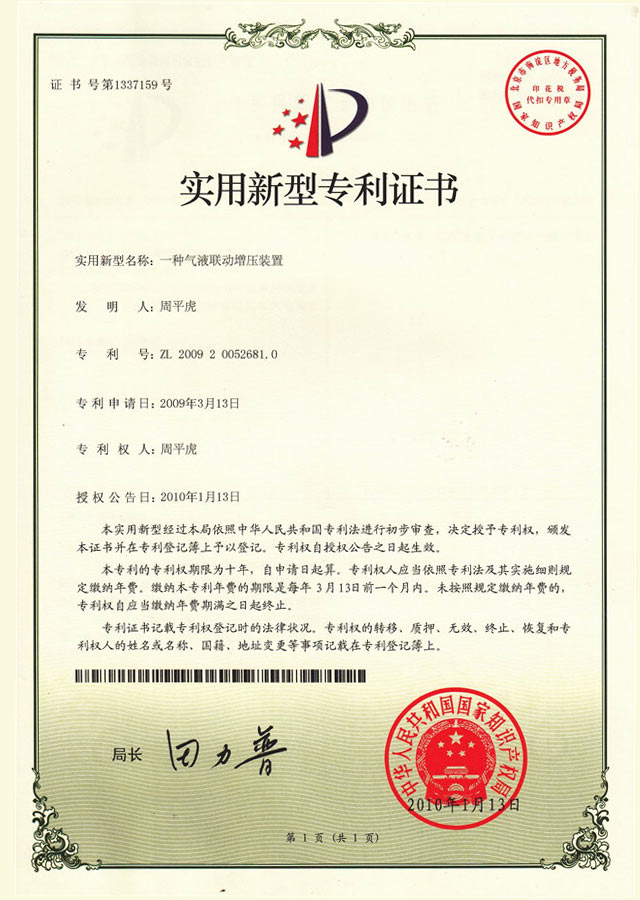

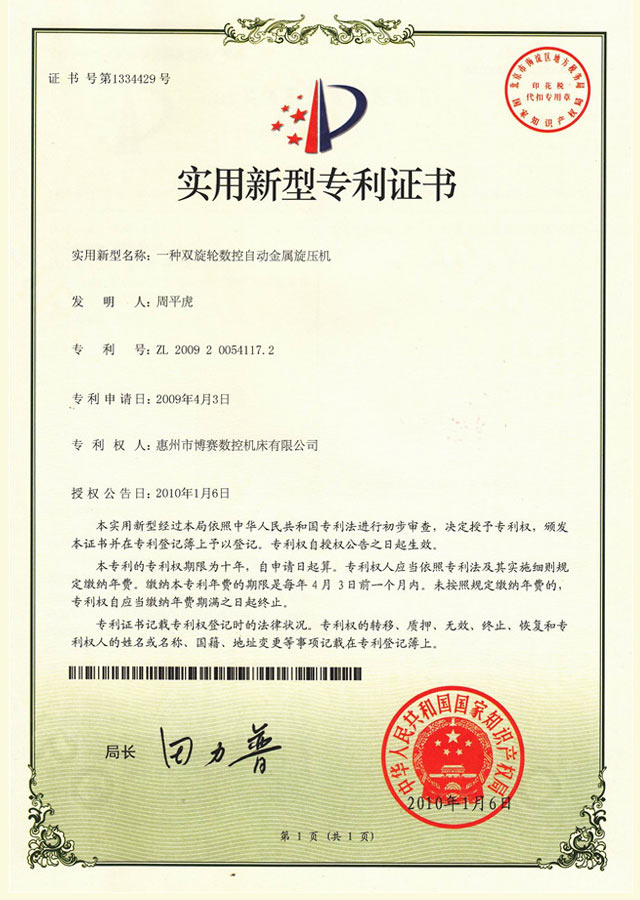

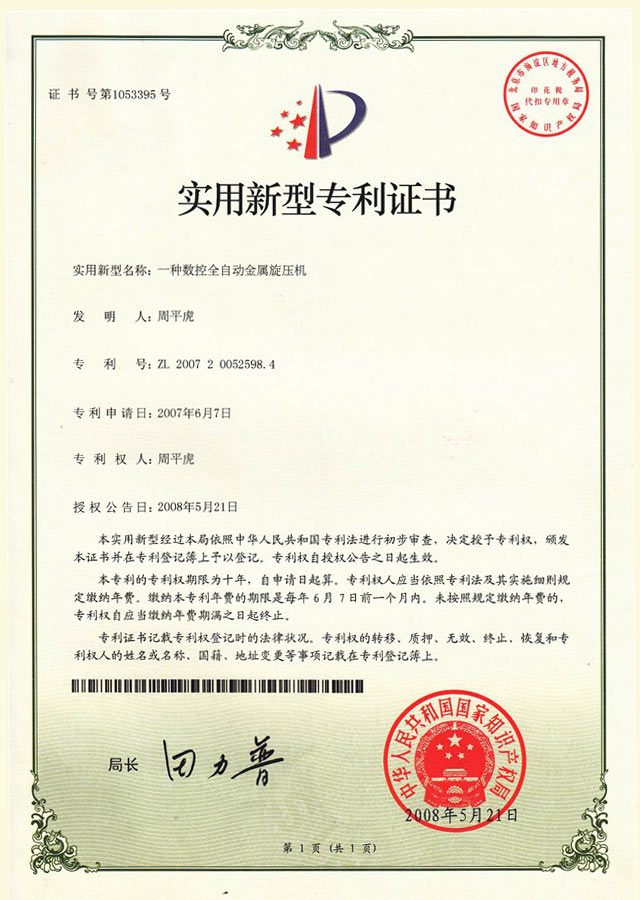

Prosper Core Technology

Technical Data:

|

项 目 名 称 |

Parameter |

计 量(单位) |

PS-CNCXY250 |

PS-CNCXY360 |

PS-CNCXY450 |

|

毛坯直径 |

Workpiece Diameter |

mm |

300 |

360 |

450 |

|

主轴电机功率 |

Main spindel power |

Km |

3.7KW |

7.5KW |

7.5KW |

|

旋轮纵向行程 |

Z axis travel |

mm |

300 |

360 |

450 |

|

旋轮横向行程 |

X axis travel |

mm |

380 |

400 |

400 |

|

主轴最高转速 |

Main spindel speed |

rpm |

4000 |

3000 |

3000 |

|

最大尾顶力 |

Tailstock force |

Kn |

10 |

15 |

15 |

|

尾顶行程 |

Tailstock travel |

mm |

300 |

300 |

300 |

|

最旋轮刀具库工位 |

Tools positions |

|

2+2 |

2+2 |

6 |

|

铝、铜板毛坯参考厚度 |

AI/CU Appx.thickness |

mm |

0.5-2 |

0.5-3.0 |

0.5-3.0 |

|

低碳钢板毛坯参考厚度 |

Steel Appx.thickness |

mm |

0.5-1.5 |

0.5-2.0 |

0.5-2.0 |

|

不锈钢板毛坯参考厚度 |

S/S Appx.thickness |

mm |

0.5-0.8 |

0.5-1.8 |

0.5-1.8 |

Specifications:

High strength Ht300 flat cast machine body

Prosper CNC spinning CNC system

Spinning tools turret/rollers

Heave duty guide and ball screw

Higt torque/high speed spindle

PROSPER SPINCAD Programming Software

BE unit(Optional)

Lubrication Spray unit(Optional)

Manipulator(Optional)

SIEMENS system with PROSPER secondly

Surface treatment tools(Optional)

Finger tools(Optional)

Yes, Once the device is fully active you can switch it between vehicles as you desire.

Yes the OBD unit can be installed in less then 30 seconds.

The devices use the cellular networks to transmit data back to our servers. All the location are obtained using a minimum of 4 satellites . This unit is currently only offered on the AT&T network.

By default the devices do not make any noise. All devices have dim LEDs. You can cover them if needed and it will not impact service.

Every passenger vehicle manufactured since 1996 has an OBD port. Heavy duty trucks manufactured after 2000 are compatible and will have one of two ports. 6 pin J1708 or 9 pin J1962. You will need an adapter or the HD Y cable.