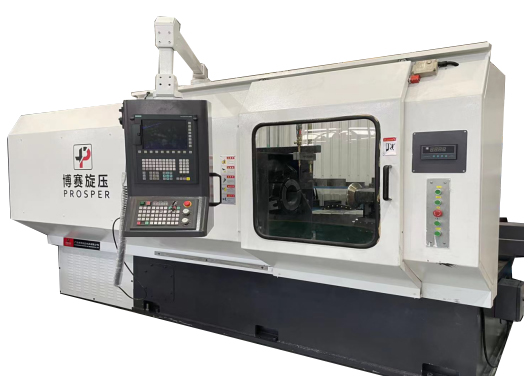

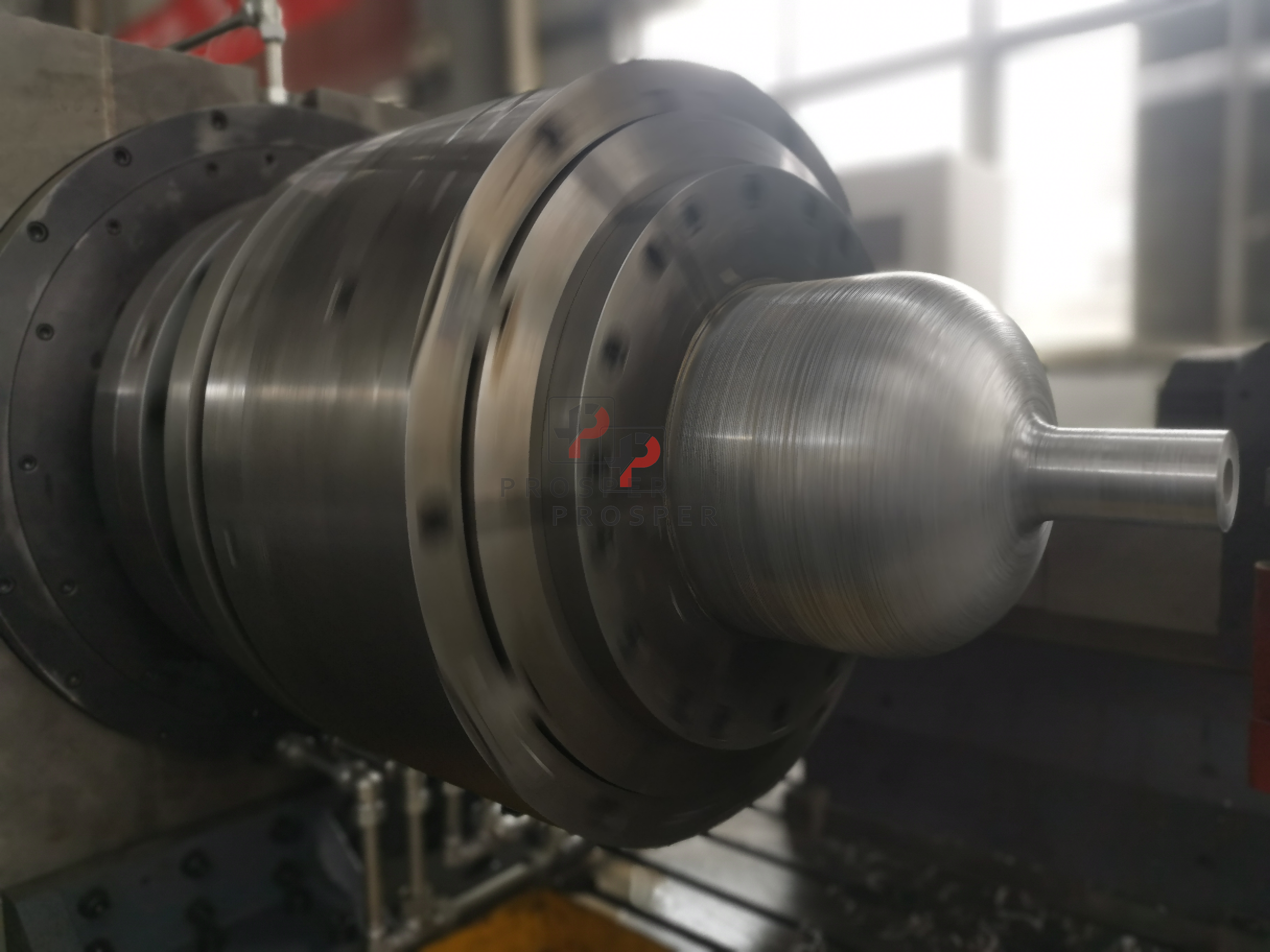

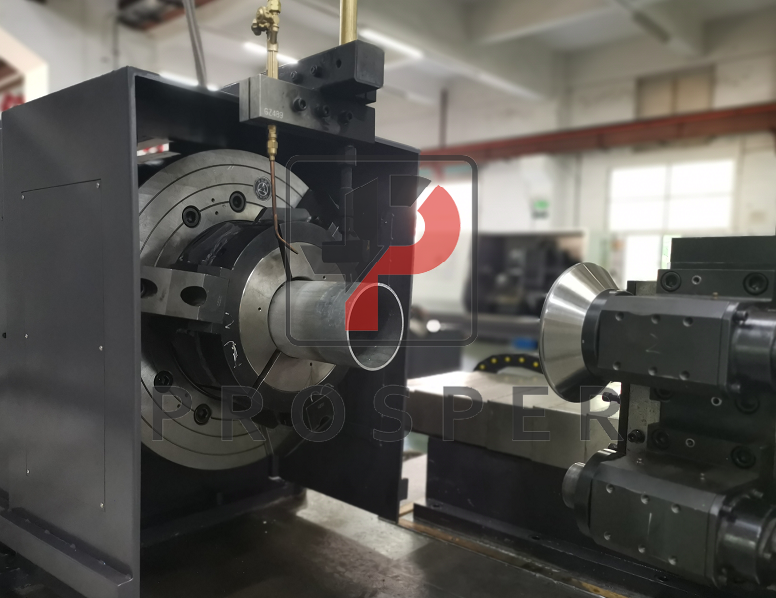

PS-CNCPN220/420/500/700/800 High Performance /High Compressive Stress Spinning Necking Machine is specially developed for the production needs of the tubular spinning parts of the exhaust system of the military, aerospace, communications, automobile, construction machinery, medical, environmental. The machine is used for for hot forming / profiling / nose forming of cylindrical shaped products,high pressure cylinders (lpg, fire extinguisher & gas etc.), pressure vessels,end closing & neck forming of high pressure cylinders / tubes like oxygen, cng, scuba diving special high pressure tubes where no welding is allowed / permissible. the utility model has the advantages of practical functions, strong professionalism, high production efficiency, batch production and trial production of the barrel type and tube type products,. It is applicable to the tube material and sealing and necking the ends of the tube and closing the end of the tube. At the same time, we can finish the trimming, flanging, curling, necking, rolling and other processing at once;

Special configuration:

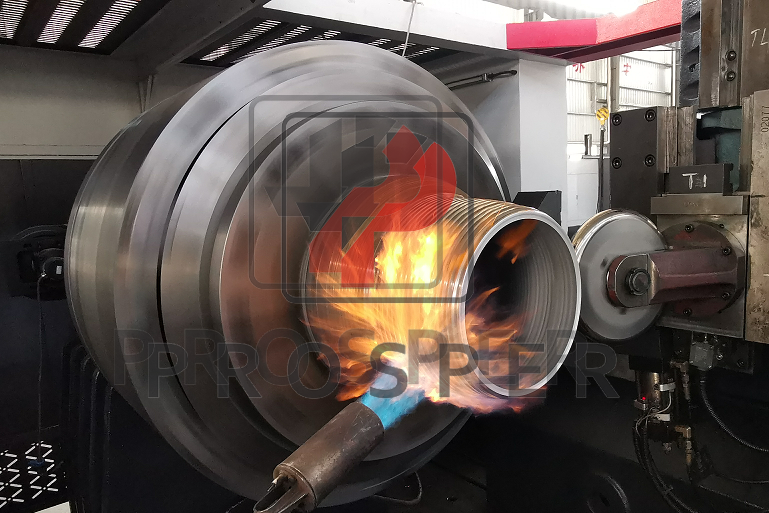

-automatic dynamic spinning heating system (oxygen + gas), oil cooling system of main shaft and tail top, water cooling partition mechanism of main shaft, water cooling partition mechanism of sliding table, water cooling partition mechanism of cutting tool, and thermal protection sheet metal.

-Material preheating, medium frequency heating mechanism, automatic loading and unloading mechanism.

-The hydraulic clamping mechanism ensures the processing stability of long pipe fittings.

-The spindle and tailstock oil cooling system adopts circulating oil cooling to ensure that the oil temperature is controlled below 30 degrees and take away too much heat. The spindle tailstock adopts lateral movement to ensure the die supporting space of long pipe fittings.

-The machine’s roller is built-in oil cooling circulation to ensure that the tool can work continuously in high temperature environment.

-The water cooling and heat insulation system of the spindle and the water coolingand heat insulation system of the sliding table adopt the circulating water test chamber to isolate the heat transfer and take away most of the heat transferred in the heating process

Technical Data:

| Parameter |

Unit |

PS-CNCSPN220 |

PS-CNCPN420 |

PS-CNCPN500 |

PS-CNCPN700 |

PS-CNCPN800 |

| MAX tube diameter |

mm |

220 |

420 |

500 |

700 |

800 |

| MAX positive spinning processed length |

mm |

200-2000 |

500-4000 |

500-6000 |

800-6000 |

800-6000 |

| Max transverse stroke |

mm |

300 |

500 |

500 |

500 |

500 |

| Max transverse X axis force |

kn |

80-1000 |

100-200 |

150-300 |

150-300 |

200-600 |

| Max longitudinal stroke |

mm |

750 |

1000 |

1000 |

1000 |

1000 |

| Max longitudinal Z axis force |

KN |

80-100 |

100-200 |

150-300 |

150-400 |

220-600 |

| Main spindle motor power |

kw |

75-110 |

110-200 |

110-200 |

160-315 |

260-400 |

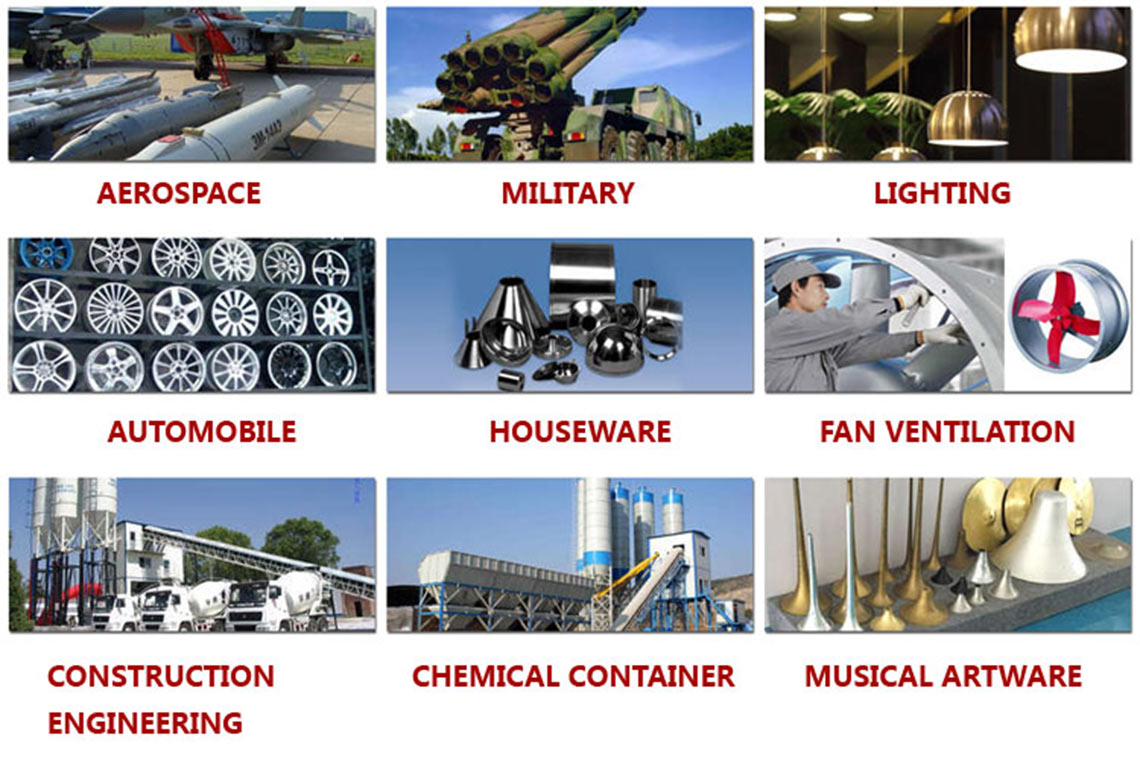

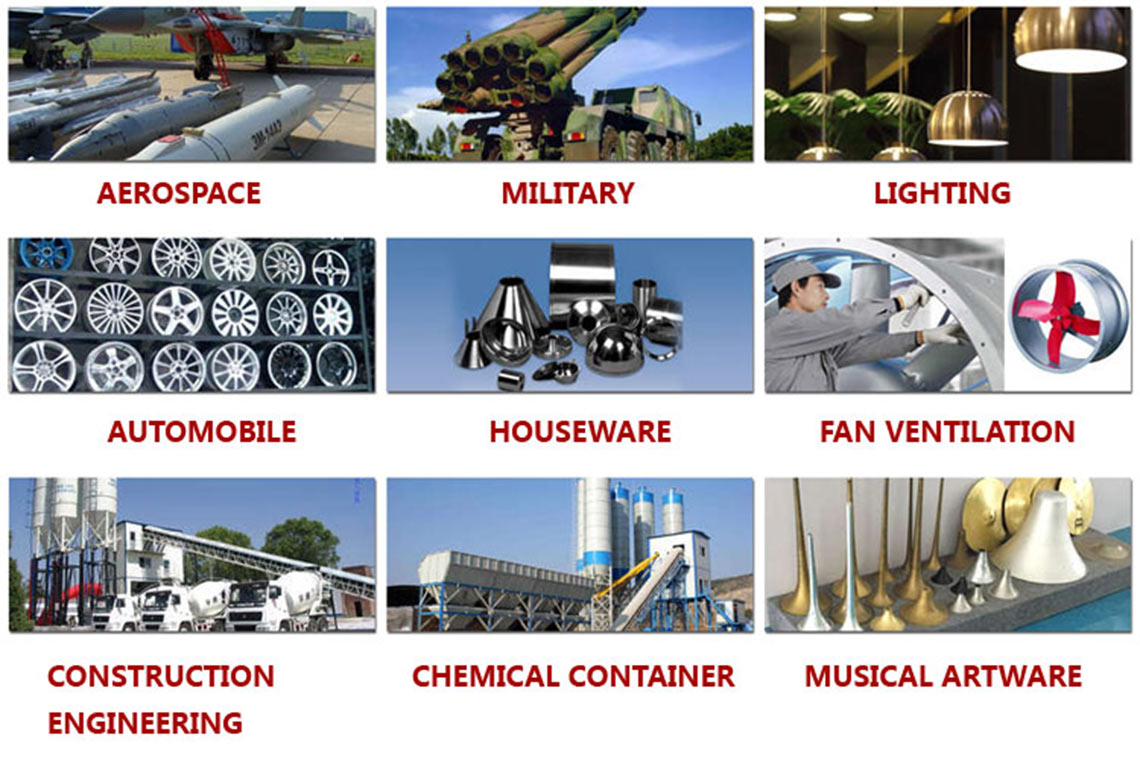

This powerful machine could be applied in a wide range of production process.It posses the firm structure, high stability, exceptional design and innovate manufacturing technology.

- 1.PS-cncsxy series has been launched in the market for nearly 6 years, which has been well received by many users and has successfully delivered nearly 300.

- 2.This serier is widely used in kitchen, household, automobile, hardware, air conditioning, fan, chemical industry and other industries. Prosper has been constantly upgrading its products with unlimited innovation.

- 3.PS-cncsxy series has a double rollers at 180 degree to ensure the high stability and efficiency for mass production with cost effective.

About Prosper

GuangDong Prosper CNC Machine Co.,Ltd is an enterprise of industrialization of new high technology which integrates research center,manufacturing,sales,customer service,and education and training school.After almost 20 years development,Prosper has nowadays owned a fifty thousand square meters operation site.Prosper values the quality of our products and services. We endeavor to provide the products and services of the most competitive advantage to our customers!

Assembly shop

The technology of workshop

The spinning experience pavilion

The technology of workshop

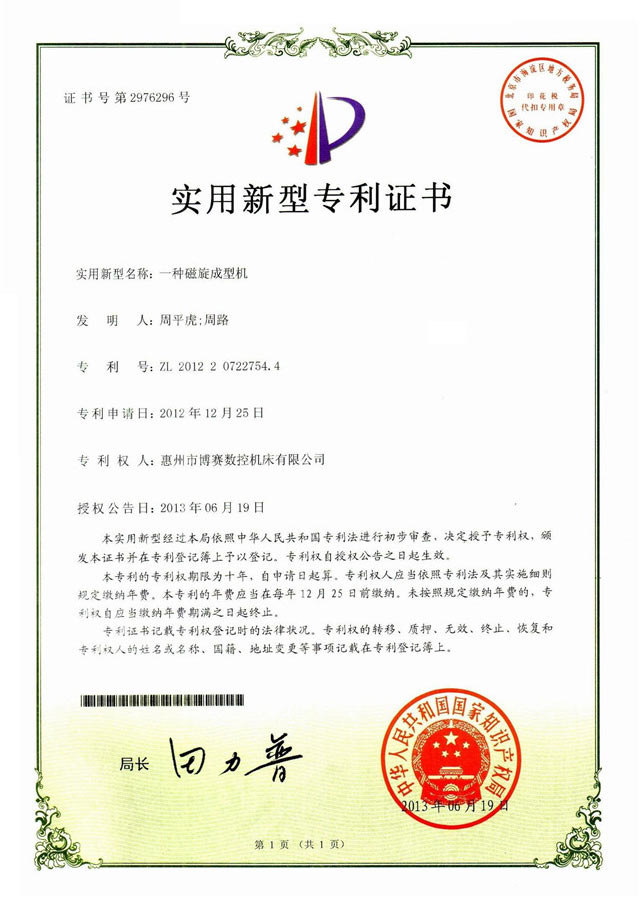

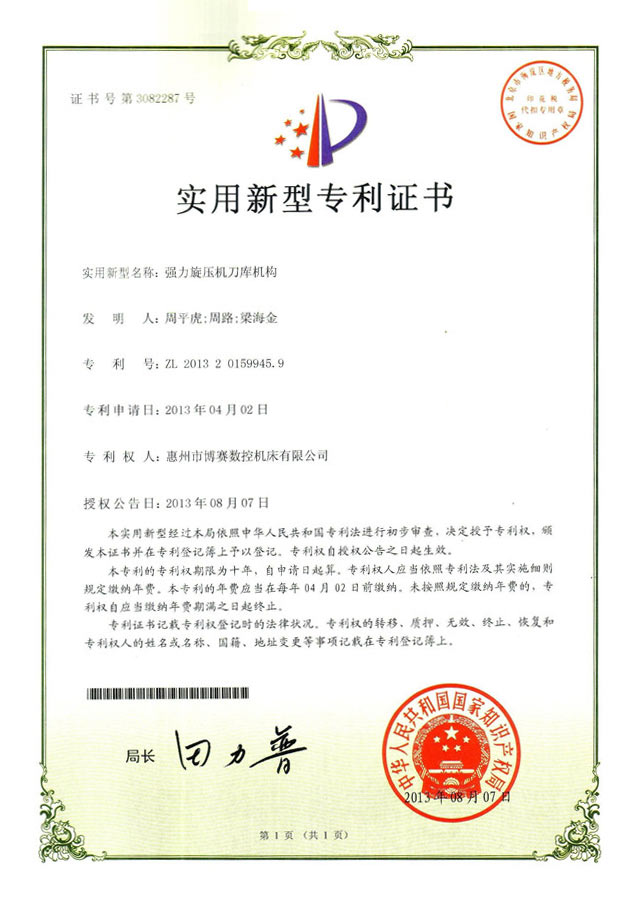

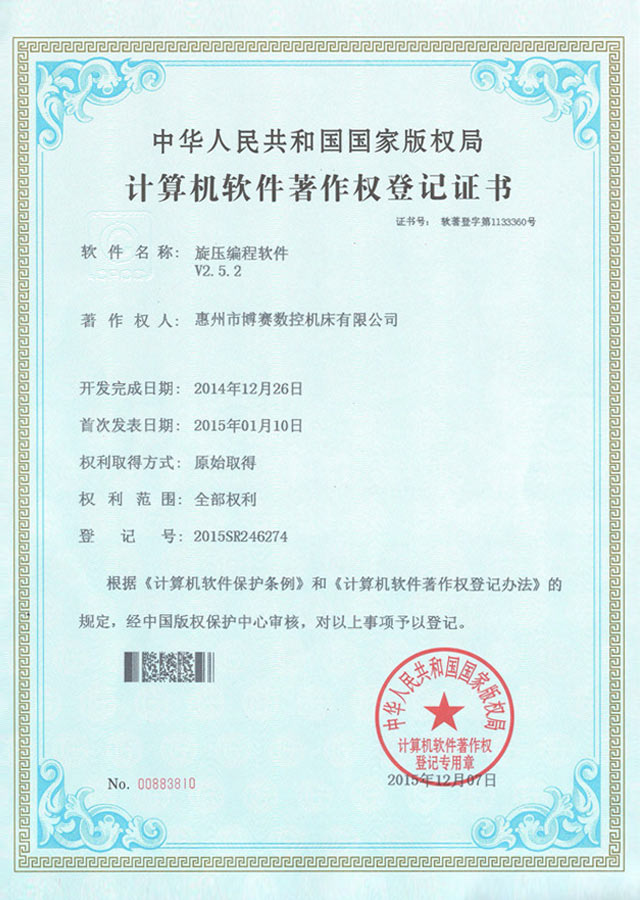

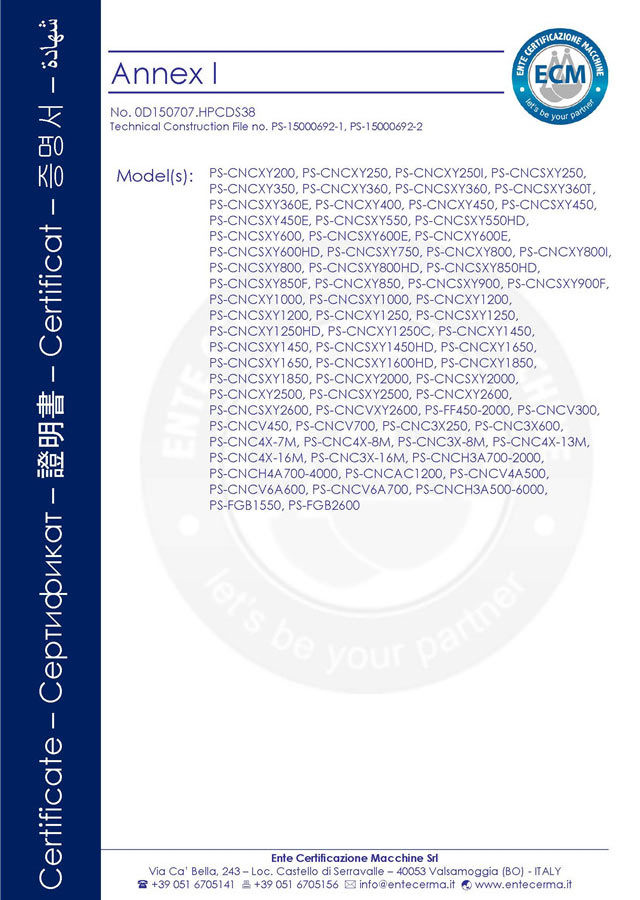

Prosper Core Technology

Application field

Cooperation strategic partner