Wheels, wheel discs, and rims are security-related and demanding components in the automotive industry. For passenger transportation, especially drive comfort and safety while driving fast are main issues. When talking about transport logistics, additional requirements need to be met regarding wheel strength for heavy loads.

A crucial aspect in drive technology is the weight. With flow-forming technology, Prosper offers an economical alternative to produce weight-optimized rims in high numbers. The prosper spinning wheel machine series has been designed and developed for producing wheels for passenger cars and trucks.

Metal spinning and flow forming are used to shape appropriate rim contours of wheels made of aluminium, steel, and other highstrength alloys.

Steel wheels for passenger cars and utility vehicles, weight-optimized light-alloy wheels for passenger cars and trucks made from forged or cast preforms

Weight-optimized wheel discs and rim rings for trucks and commercial vehicles

Prosper launched for multi type cnc spinning machine in accordance with automotive wheel industry,

which satisfies the spinning processing of forged, cast and multi-piece aluminum alloy wheel.

The vertical three-roller spinning machine / two-roller spinning machine, horizontal two-roller

spinning machine / single-roller spinning machine, can be customized for the customer's products

for the machine and process solutions, to achieve turnkey projects,providing process support and

after-sales service to customers for life, maximizing customer benefits.

Technical Data:

|

Parameter |

|

PS-CNCVW602 |

PS-CNCVW702 |

PS-CNCVW703S |

|

APPLICATION |

|

Casting/Forging Aluminum Wheel |

Casting/Forging Aluminum Wheel |

Casting/Forging Aluminum Wheel |

|

Maximum rotation diameter |

mm |

600 |

720 |

720 |

|

Minimum rotation diameter |

mm |

320 |

410 |

410 |

|

Max double center distance |

mm |

700 |

900 |

1100 |

|

Tool position |

PCS |

2 |

2 |

3 |

|

Longitudinal sliding table stroke |

mm |

460 |

520 |

600 |

|

Transverse sliding table stroke |

mm |

200 |

200 |

200 |

|

Longitudinal sliding table force |

Kn |

250KN*2 |

400 |

400KN*3 |

|

Transverse sliding table force |

KN |

250KN*2 |

400 |

400KN*3 |

|

Main spindle motor power |

KW |

2*100KW |

2*132KW |

2*132KW |

|

Tailstock force |

KN |

10-300KN |

10-400KN |

10-500KN |

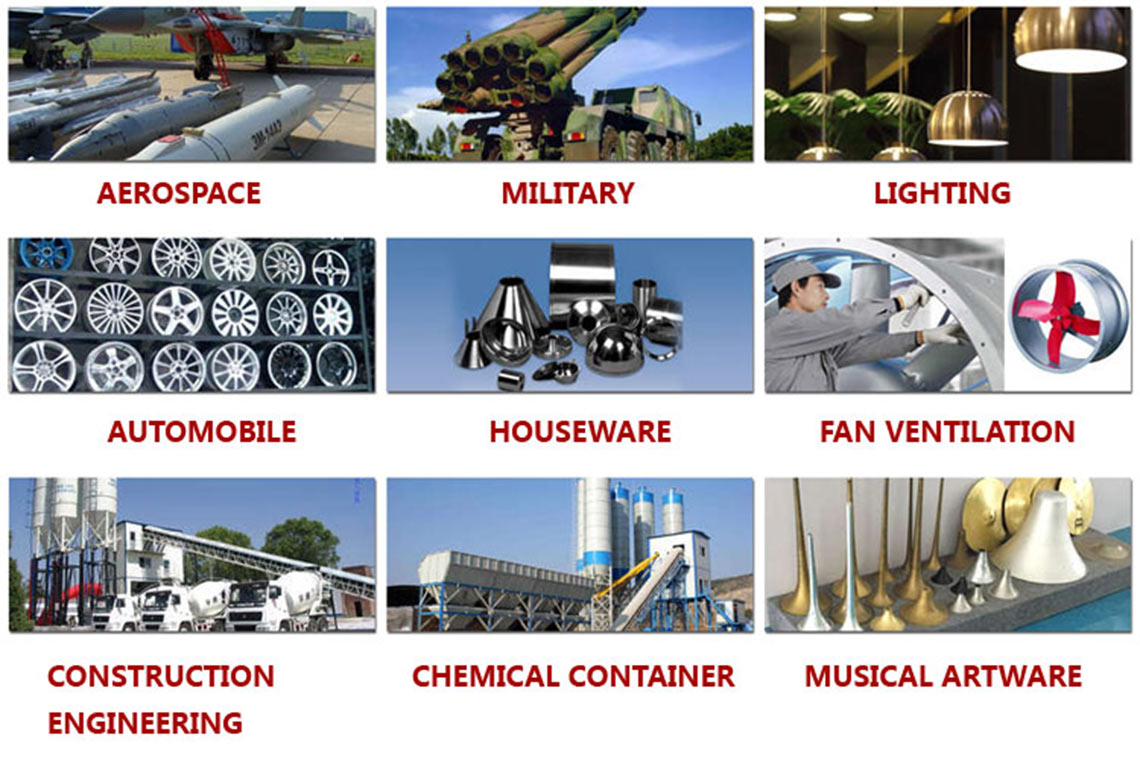

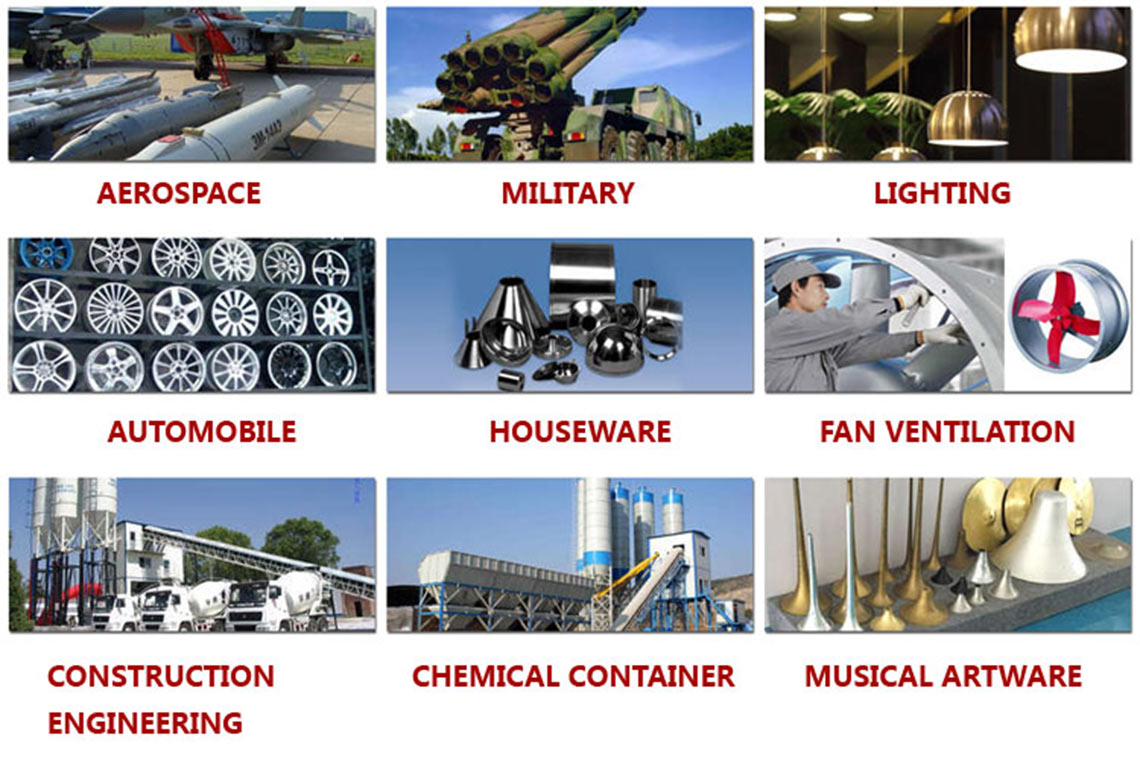

Applications:MILITARY,SPACEFLIGHGT,AVITATION WEAPONS AND OTHER MANUFACTURING INDUSTRIES

-

1.THREE ROLLERS POWER SPINNING

-

2.SYNCHRONIZING SPINNING AND STAGGER SPINNING

-

3.MULTI AXISES/NULTI CHANNEL CNC CONTROL SYSTEM

-

APPLE TO CARBON STEEL ALLOY STEEL,ATAINLESS STEEL,NONFERROUS METAL AND OTHER ALLOY MATERIAL

About Prosper

GuangDong Prosper CNC Machine Co.,Ltd is an enterprise of industrialization of new high technology which integrates research center,manufacturing,sales,customer service,and education and training school.After almost 20 years development,Prosper has nowadays owned a fifty thousand square meters operation site.Prosper values the quality of our products and services. We endeavor to provide the products and services of the most competitive advantage to our customers!

Assembly shop

The technology of workshop

The spinning experience pavilion

The technology of workshop

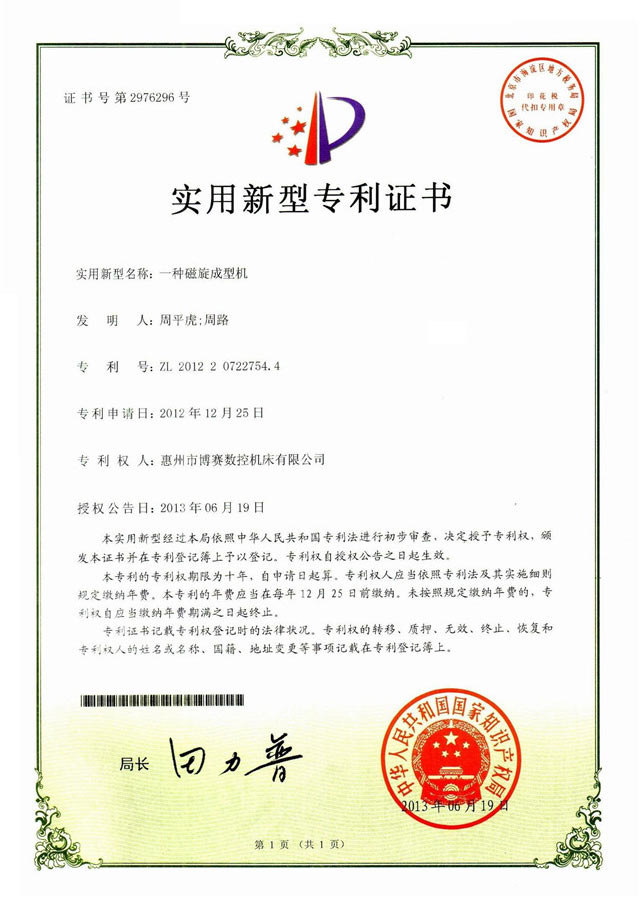

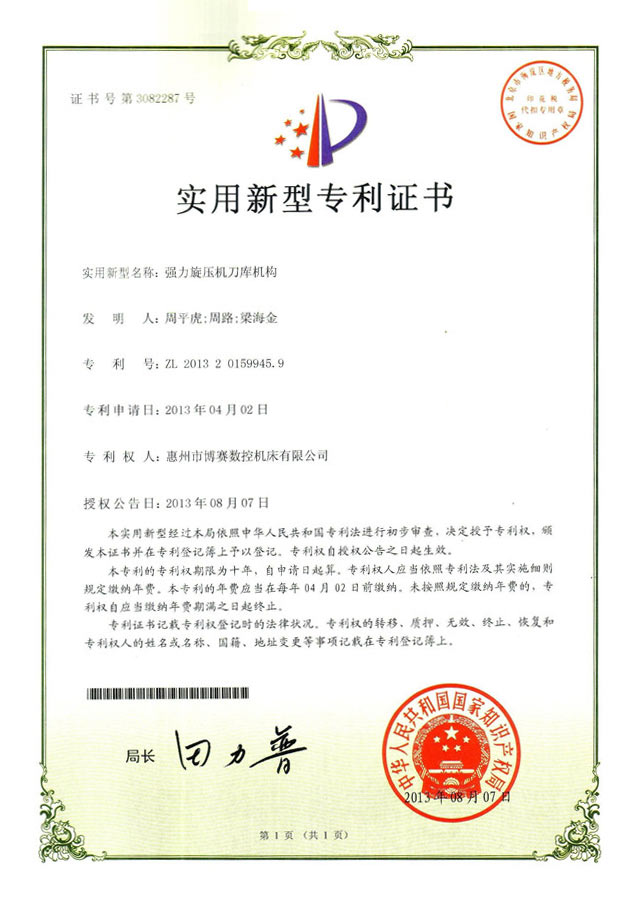

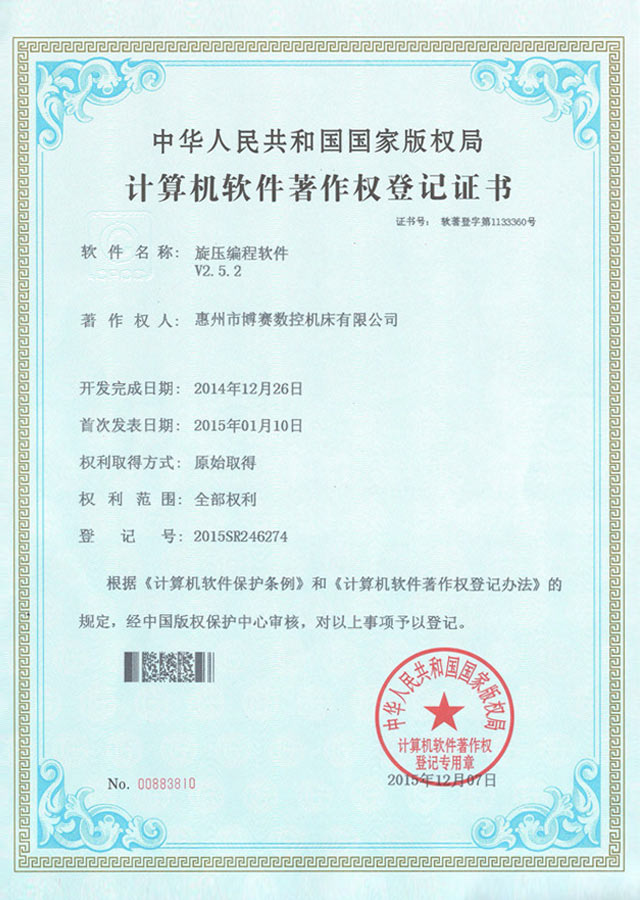

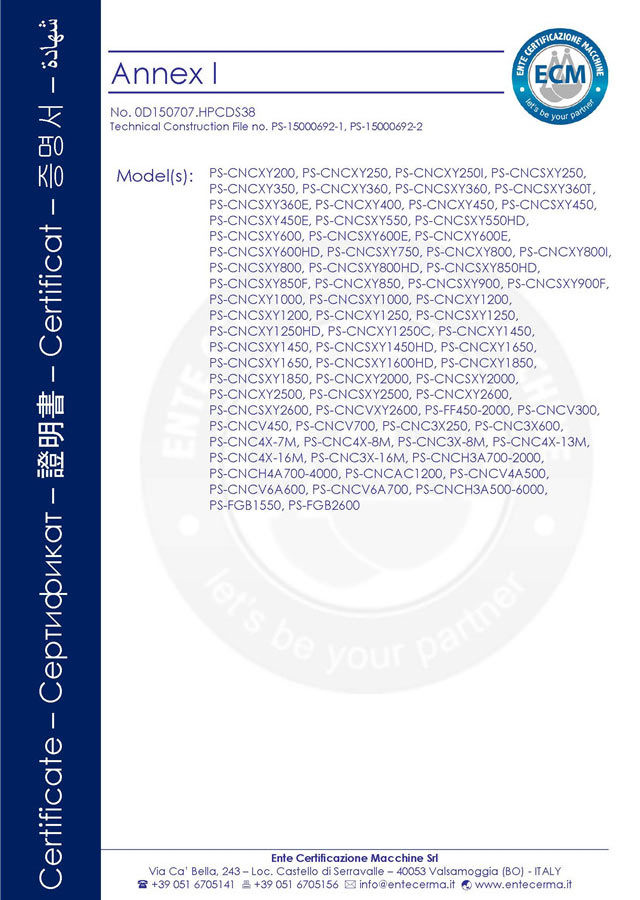

Prosper Core Technology

Application field

Cooperation strategic partner

|

APPLICATION |

|

Casting/Forging Aluminum Wheel |

Casting/Forging Aluminum Wheel |

Casting/Forging Aluminum Wheel |

|

Maximum rotation diameter |

mm |

600 |

720 |

720 |

|

Minimum rotation diameter |

mm |

320 |

410 |

410 |

|

Max double center distance |

mm |

700 |

900 |

1100 |

|

Tool position |

PCS |

2 |

2 |

3 |

|

Longitudinal sliding table stroke |

mm |

460 |

520 |

600 |

|

Transverse sliding table stroke |

mm |

200 |

200 |

200 |

|

Longitudinal sliding table force |

Kn |

250KN*2 |

400 |

400KN*3 |

|

Transverse sliding table force |

KN |

250KN*2 |

400 |

400KN*3 |

|

Main spindle motor power |

KW |

2*100KW |

2*132KW |

2*132KW |

|

Tailstock force |

KN |

10-300KN |

10-400KN |

10-500KN

|

Yes, Once the device is fully active you can switch it between vehicles as you desire.

Yes the OBD unit can be installed in less then 30 seconds.

The devices use the cellular networks to transmit data back to our servers. All the location are obtained using a minimum of 4 satellites . This unit is currently only offered on the AT&T network.

By default the devices do not make any noise. All devices have dim LEDs. You can cover them if needed and it will not impact service.

Every passenger vehicle manufactured since 1996 has an OBD port. Heavy duty trucks manufactured after 2000 are compatible and will have one of two ports. 6 pin J1708 or 9 pin J1962. You will need an adapter or the HD Y cable.