Servo driver of CNC spinning machine feed system

Date: Apr,15 2020 View:

Servo driver of CNC spinning machine feed system

In the servo feed system of the spinning roller of the CNC spinning machine, the servo driver is the key component. It receives the feed command signal sent by the numerical control system and converts it into angular displacement or linear displacement, thereby driving the rotary bidirectional carriage to achieve the required motion.

The servo drive should meet the following requirements

①The displacement accuracy is high, that is, the difference between the actual displacement and the commanded displacement is small.

②It has a large overload capacity for a long time to meet the requirements of low speed and large torque. Generally, a DC servo motor requires an overload of 4 to 6 times within a few minutes without damage.

③The speed range is wide, and the motor can run smoothly from the lowest speed to the highest speed, and the torque fluctuation is small, especially at low speed (such as 1r / min, or lower), the speed is stable and there is no crawling phenomenon.

④Can withstand frequent starting and reverse rotation after braking

At present, in the closed-loop feed servo system of CNC spinning machine, the servo drive machine mainly adopts AC and DC servo motors, and AC servo motors gradually form the mainstream. Stepper motors (mainly power type stepper motors) are only used on some small and economical open-loop CNC spinning machines.

(1) Stepper motor

Stepper motor is an actuator that is controlled by electric pulse signal and converts the electric pulse signal into corresponding angular displacement. The angular displacement is proportional to the number of electrical pulses, and the speed is proportional to the frequency of the electrical pulses. The speed of the motor can be adjusted by changing the pulse frequency. If the windings of certain phases remain energized after shutdown, they have self-locking capability. The stepper motor has a fixed number of steps per revolution, and theoretically its step error will not accumulate.

(2) DC servo motor

The DC servo motor has good starting, braking and speed regulation characteristics, which can facilitate smooth stepless speed regulation in a wide range. Especially the large inertia and wide speed DC servo motor developed in the 1970s has many advantages, and it has been widely used in CNC machine tools and CNC spinning machines. Large inertia and wide speed DC servo motors are divided into two types: electric excitation and permanent magnet excitation. But the latter is dominated by the latter (permanent magnet type) motor.

(3) AC servo motor

Since the 1980s, AC servo drive technology has made breakthrough progress. According to statistics, Germany's 1988 machine tool feed drive has accounted for 80% of the AC servo motor drive. Compared with the DC motor, the AC motor has the characteristics of small rotor inertia, good dynamic response, small mass, large capacity, high speed, etc., which can be achieved Good speed control performance. AC servo motors can be divided into AC asynchronous (induction) motors and AC synchronous motors. At present, water-magnetic AC synchronous servo motors are mostly used in the feed drive of CNC machine tools.

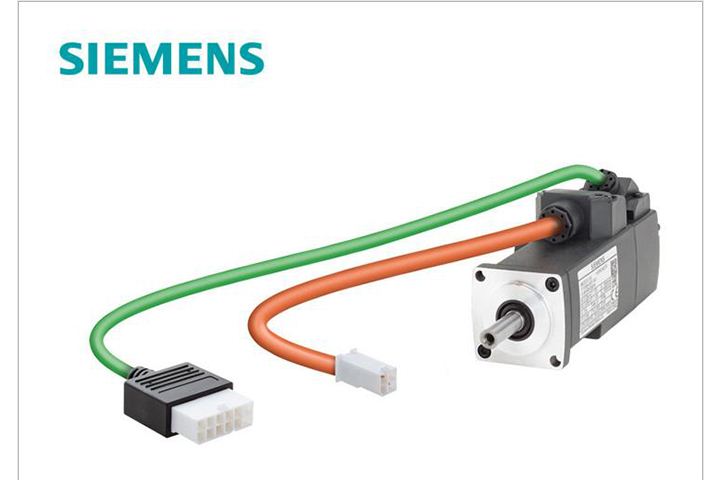

The CNC metal spinning machines which are made by Prosper all using Siemens servo motors to guarantee easy operation, excellent servo performance and reliable displacement.