Workpiece Quality in Metal Spinning Technology

Date: Jul,22 2020 View:

Workpiece Quality in Metal Spinning Technology

A.The main content of workpiece quality

The quality of workpiece is the basic part of spinning process. In the case of important, high requirements and mass production, it is the priority. The quality of the workpiece generally includes two contents:

One is the manufacturing accuracy of the workpiece, the other is the performance.

The manufacturing accuracy of workpiece can be divided into three aspects: geometric dimensional accuracy, geometric tolerance accuracy and surface quality. The geometric accuracy includes diameter, length, wall thickness, cone angle and arc radius, etc. The geometric accuracy includes straightness, roundness, cylindricity, coaxiality, perpendicularity, circle runout, end face runout and workpiece flare at the end. In addition to the surface roughness, the surface quality of the workpiece also includes the material quality of the surface layer. The performance of the workpiece can also be divided into three aspects: metallographic structure, mechanical properties and performance. In terms of metallographic structure, there are metal fiber streamlines, grain size, low-power structure and residual stress of spinning parts. The mechanical properties include hardness, strength and plasticity, as well as the uniformity and directionality of these properties. The service performance includes working life, long-term storage stability and other special requirements.

In short, the content of workpiece quality is quite extensive, but for a specific workpiece, the quality requirements are focused, and the requirements are different. That is, the specific situation is analyzed in detail.

B.The main factors of workpiece quality

1. Blank size and manufacturing quality

Blank size (diameter, wall thickness, etc.) and its manufacturing and installation positioning accuracy, blank material organization performance and uniformity have great influence on the quality of the workpiece, especially the thickness and uniformity of the blank, the accuracy of inner diameter and the state of metal structure.

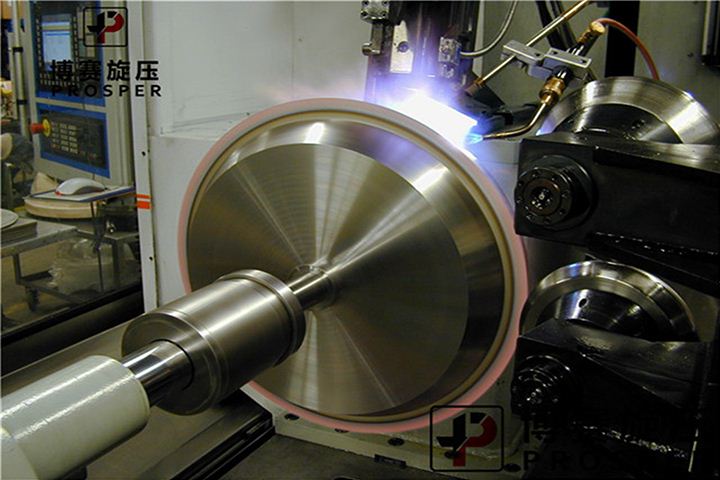

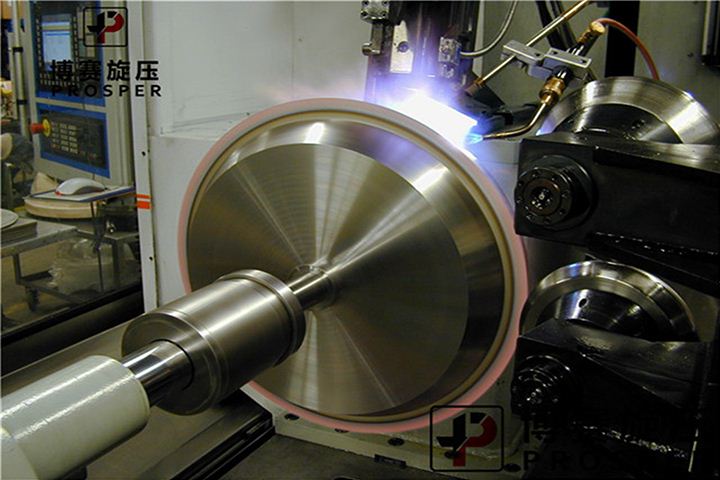

2. Equipment accuracy, stiffness and adjustment

During the spinning process, the laws and accuracy of the relative motion of the parts of various mechanisms involved in the forming process and their adjustments have a direct impact on the forming accuracy of the workpiece. Among them, the rigidity of the spinning equipment determines the concession and vibration of the spinning process system during the spinning process, so the impact on the manufacturing accuracy of the workpiece is very obvious.

The shape and parameters of the roller structure, such as working angle, working radius, roller diameter and surface roughness, etc., have a direct impact on the spinning process, and therefore also affect the manufacturing quality of the workpiece. Mandrel manufacturing, installation, and adjustment accuracy also directly affect the dimensional accuracy of the workpiece diameter and the roughness of the inner surface, as well as the roundness, cylindricity, and coaxiality of the inner and outer surfaces.

3. Spinning process factors

Spinning process factors have a very obvious influence on the machining accuracy of the workpiece. By properly adjusting or changing certain process parameters, it is often possible to effectively improve the machining accuracy of the spinning parts. These process factors mainly include the spinning direction, the number of spinning path, the thinning rate of the path, the feeding amount of the roller, the rotating speed of the spindle, the gap between the roller and the mold, and the offset distance of the multi-wheel spinning , heating temperature during hot spinning and process cooling during cold spinning, etc.